the expansion of our warehouses is complete

- HOMEABOUT USQUALITYTECHNOLOGYMATERIALS

- WOODMETALPVC AND DRYWALLCONCRETECATALOG

-

AMBROVIT SpA

Viale Giulio Natta, 29

27026 Garlasco (PV) – ITALY The ISO 9001 certification attests Ambrovit’s commitment to quality and safety in accordance with international standards.The ETA and CE Certifications distinguishes Ambrovit for the quality of its products dedicated to the construction sector.

The ISO 9001 certification attests Ambrovit’s commitment to quality and safety in accordance with international standards.The ETA and CE Certifications distinguishes Ambrovit for the quality of its products dedicated to the construction sector.

Blockframe and Drywall

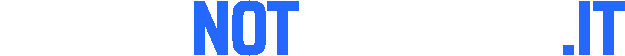

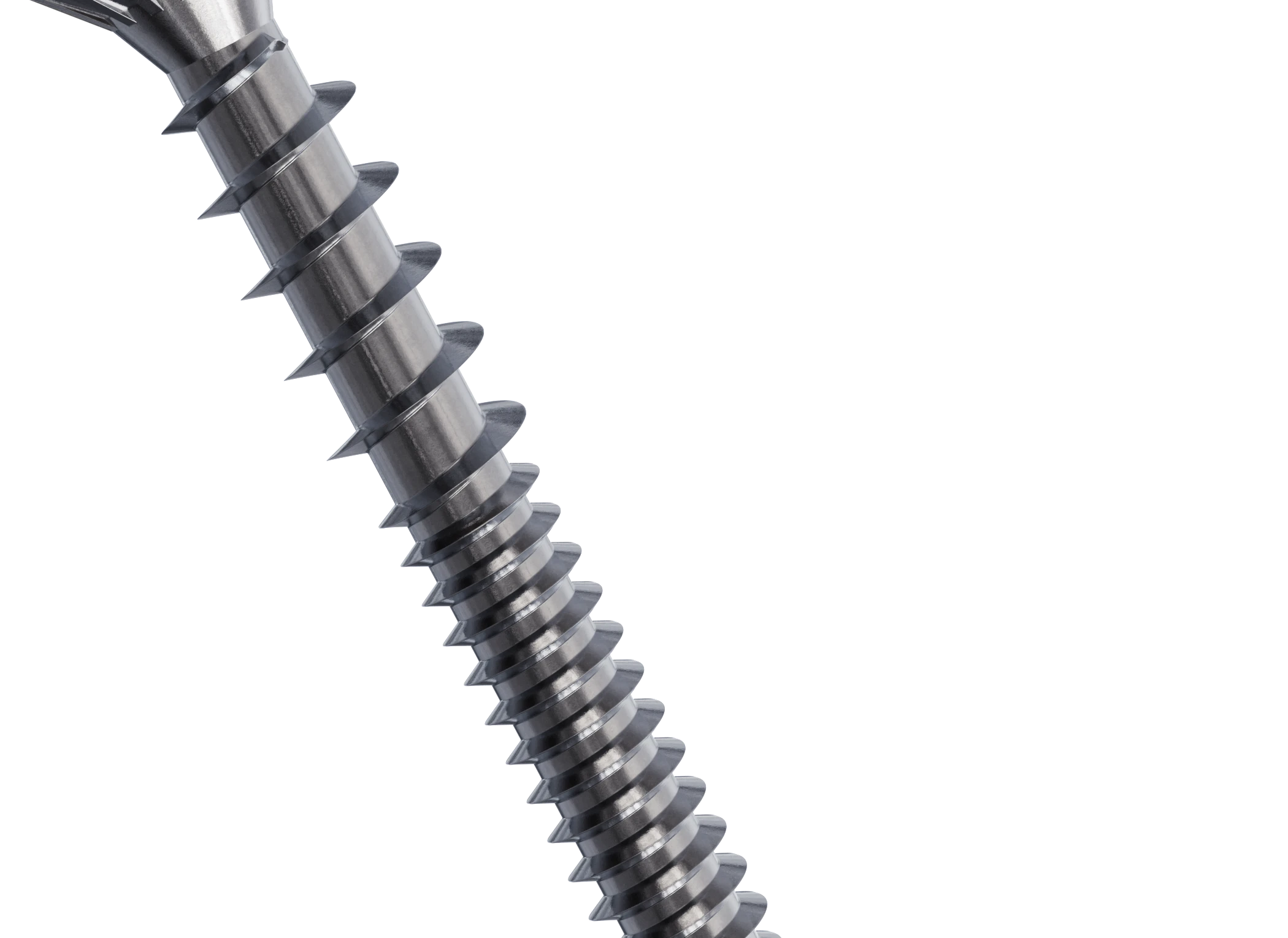

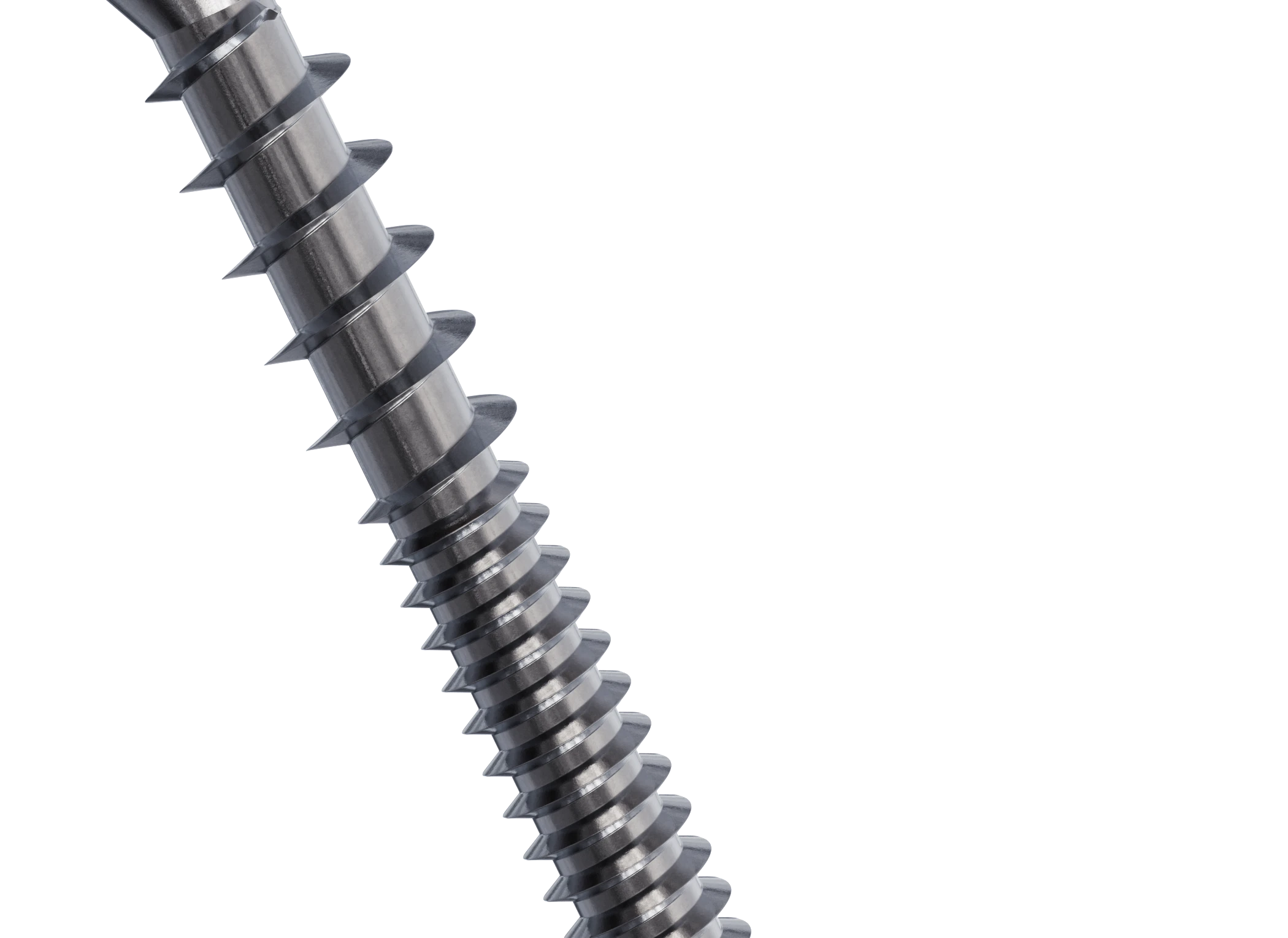

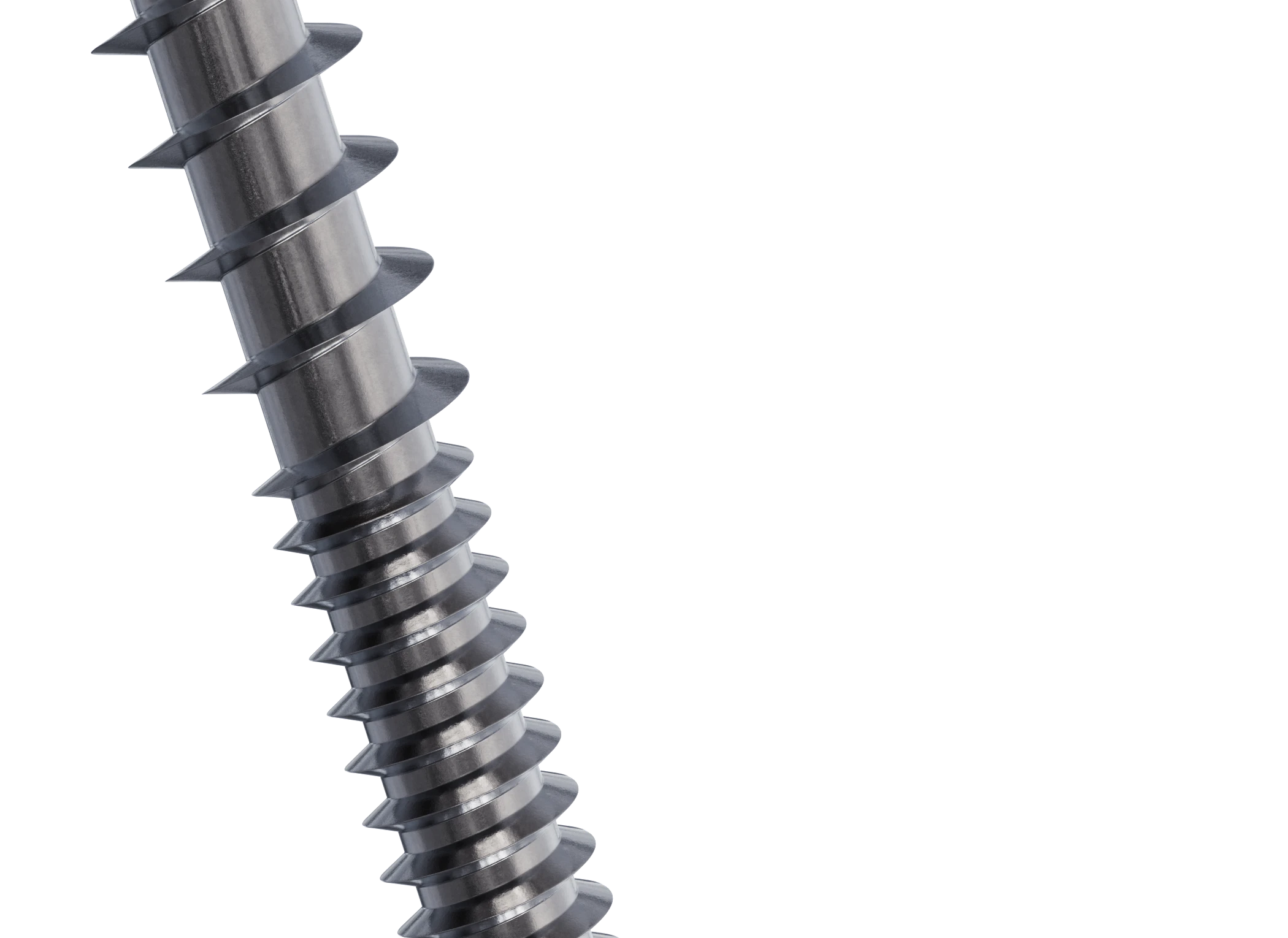

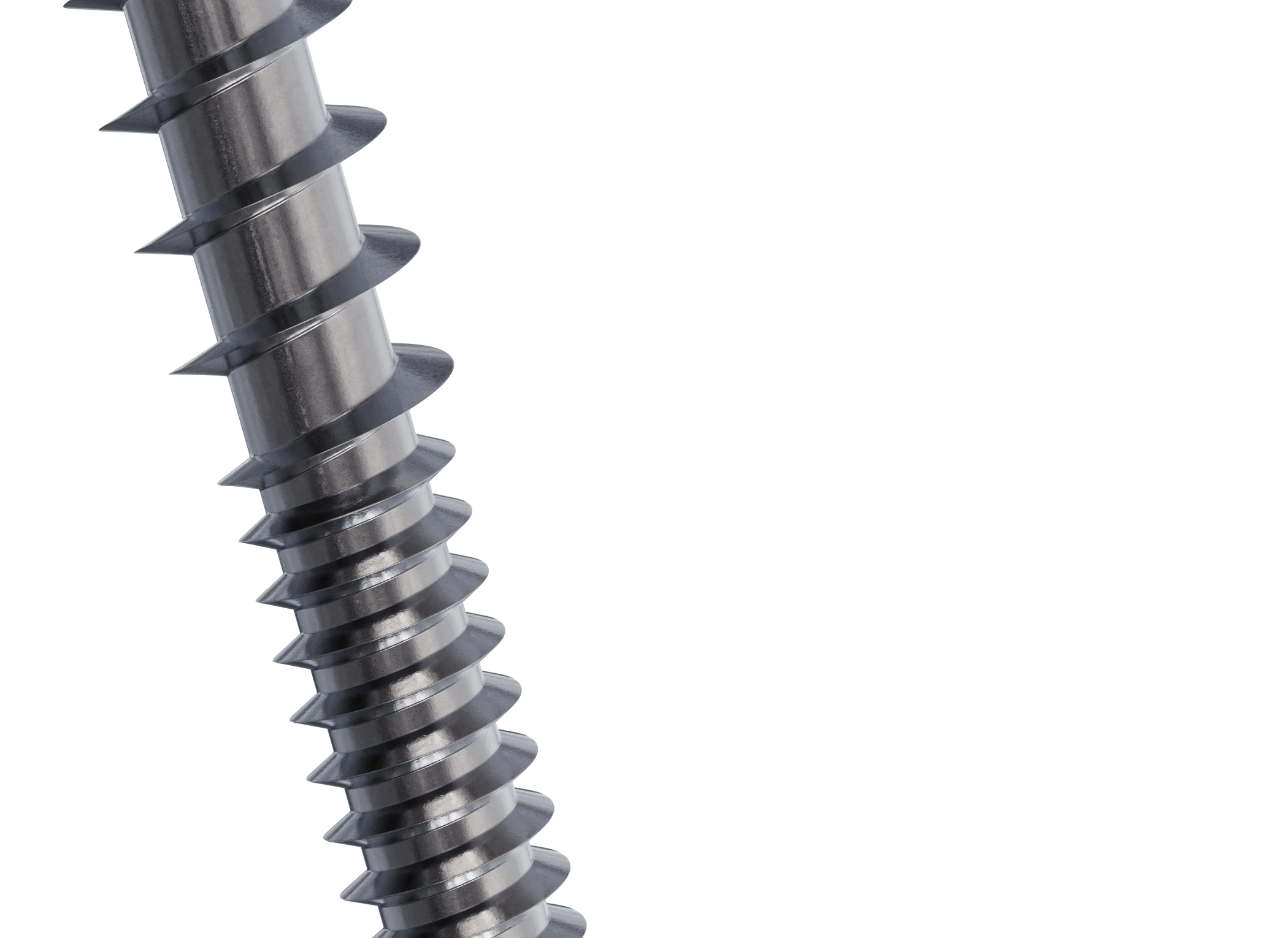

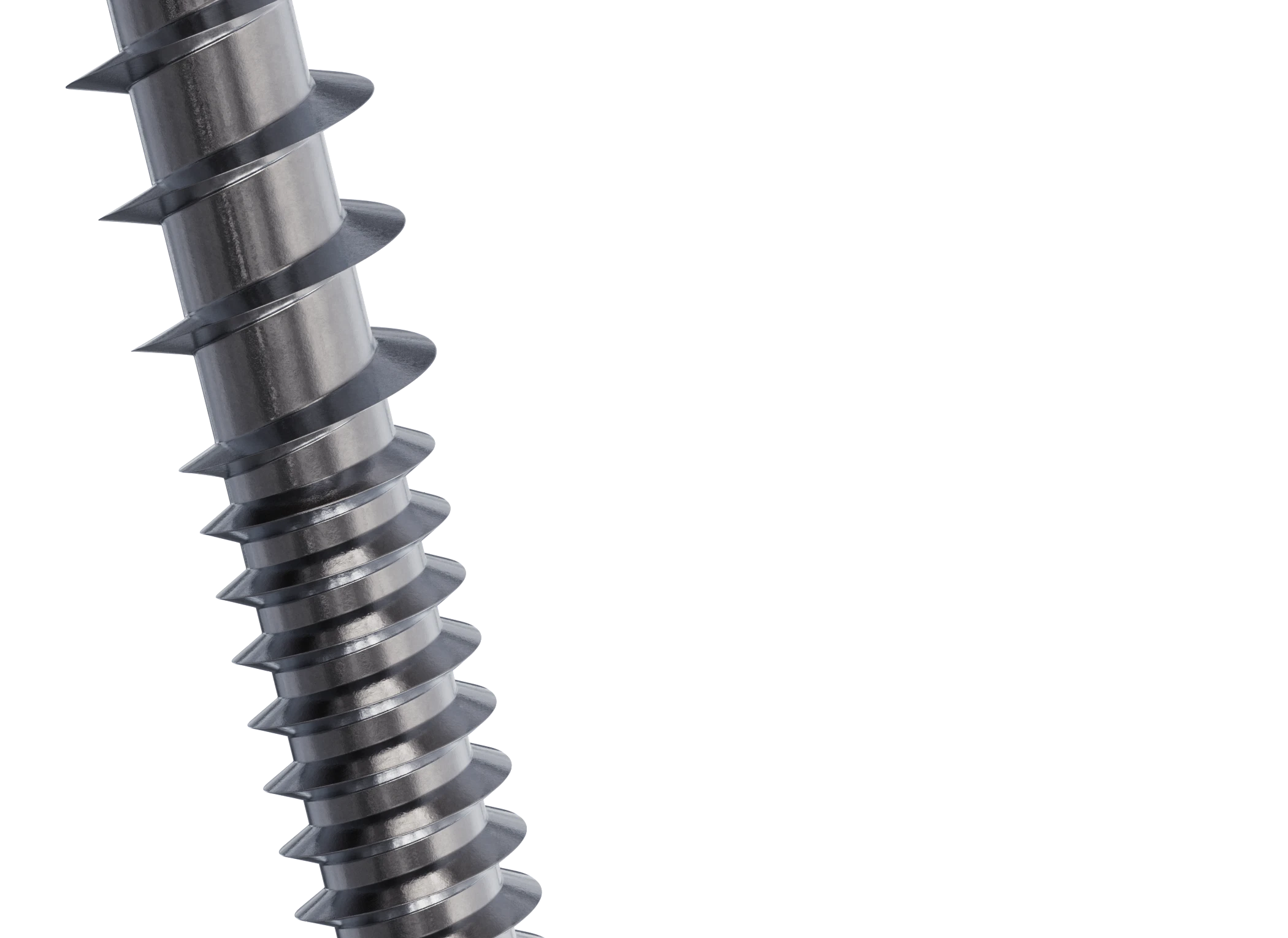

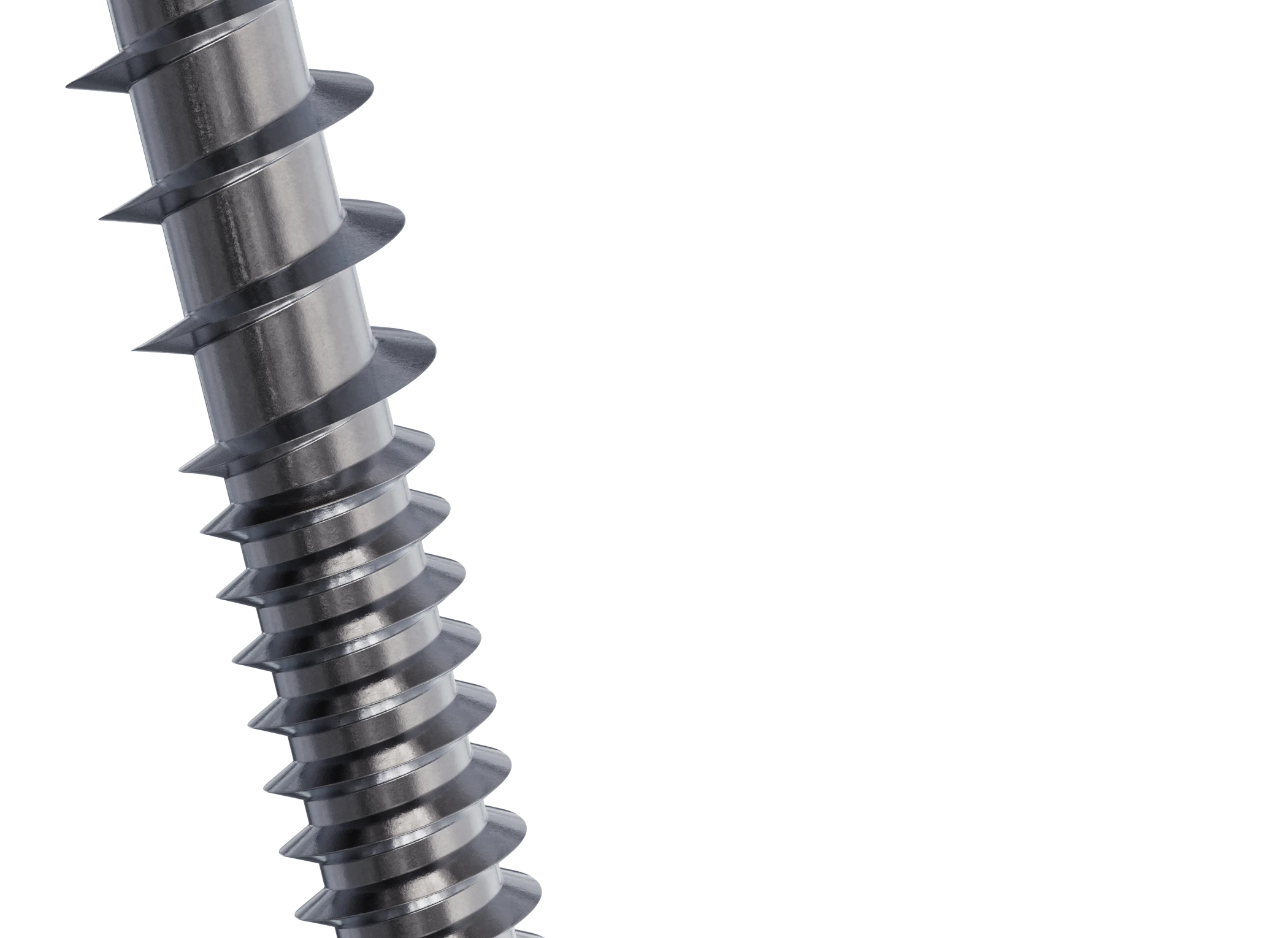

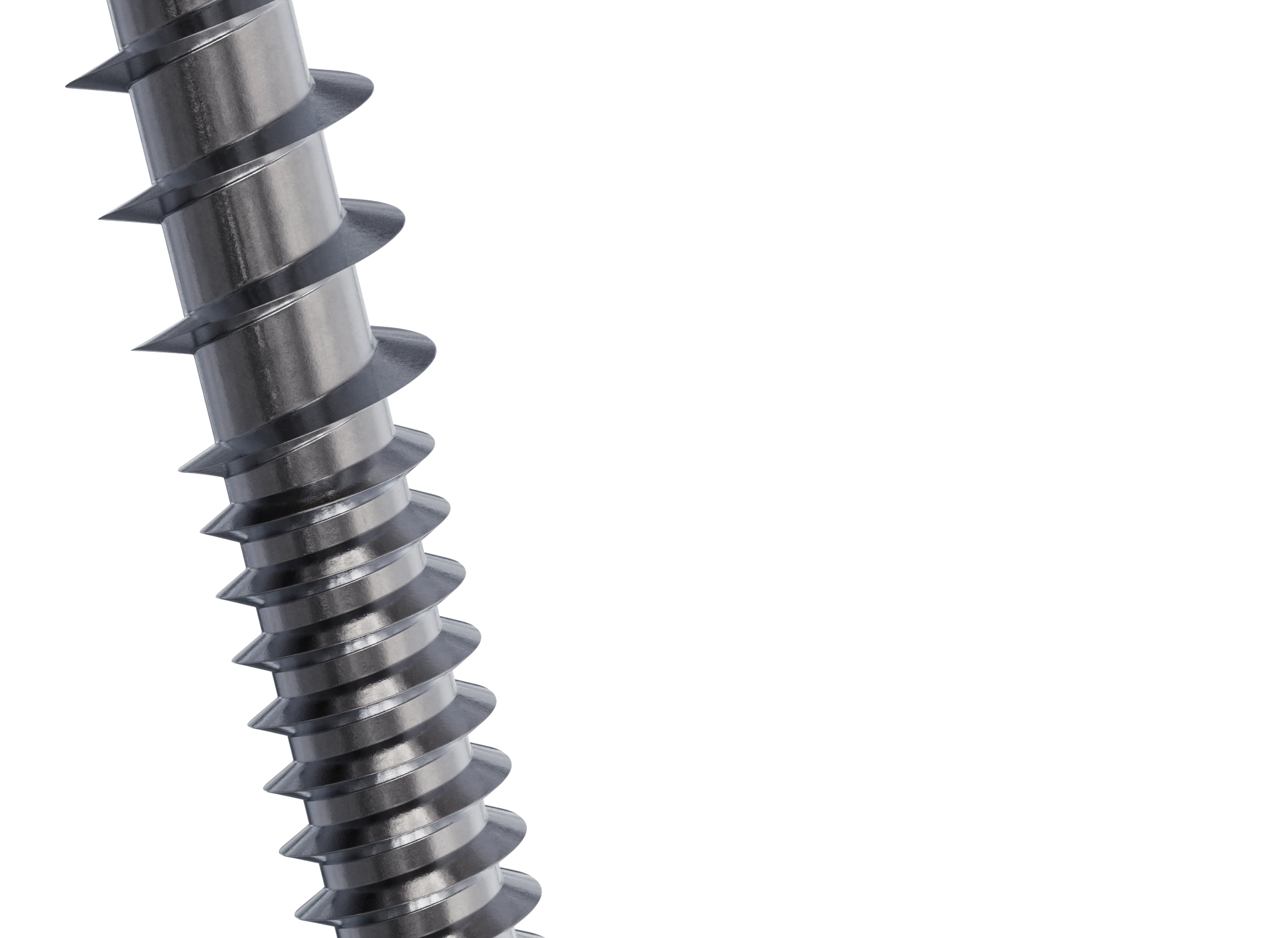

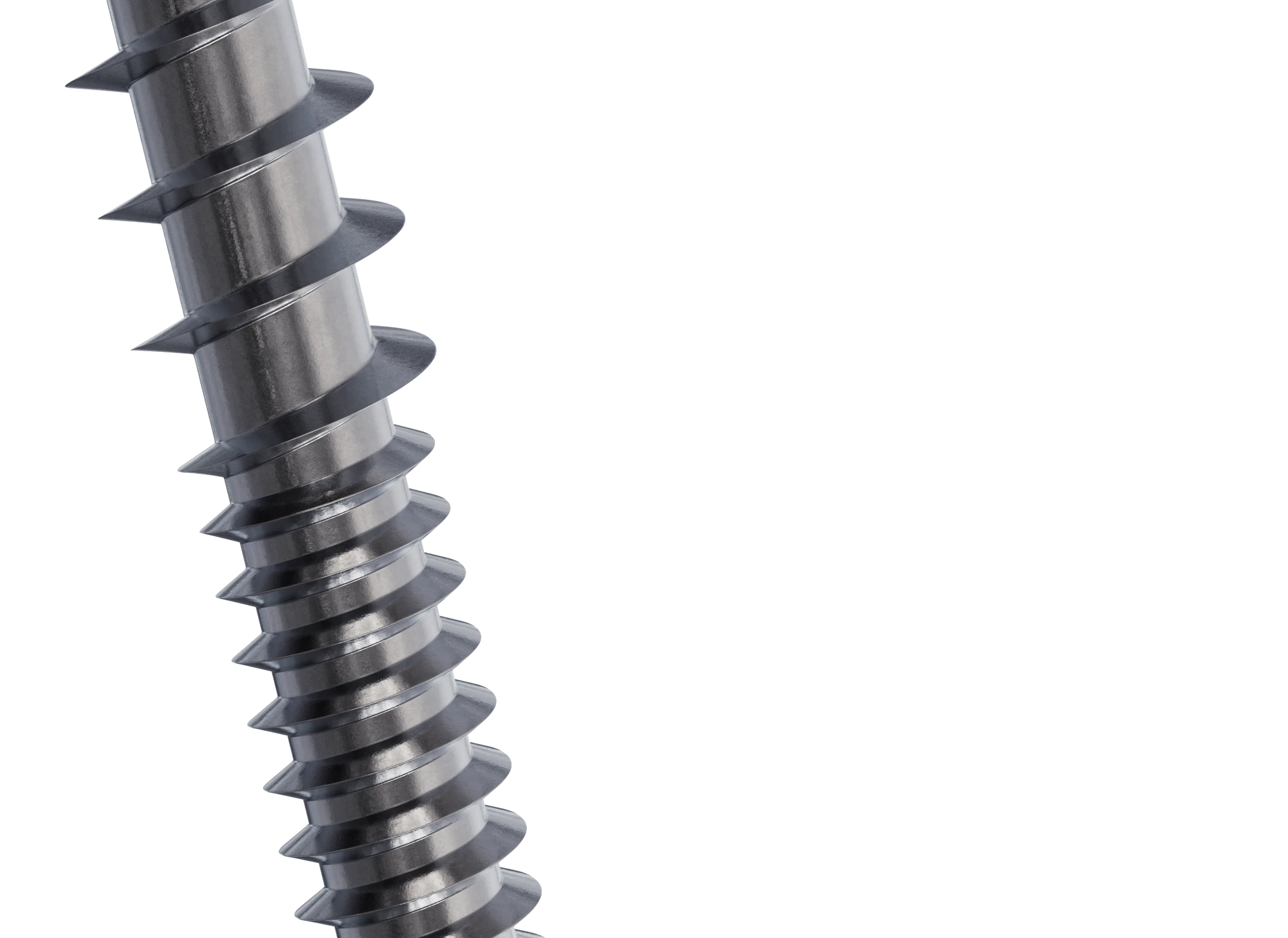

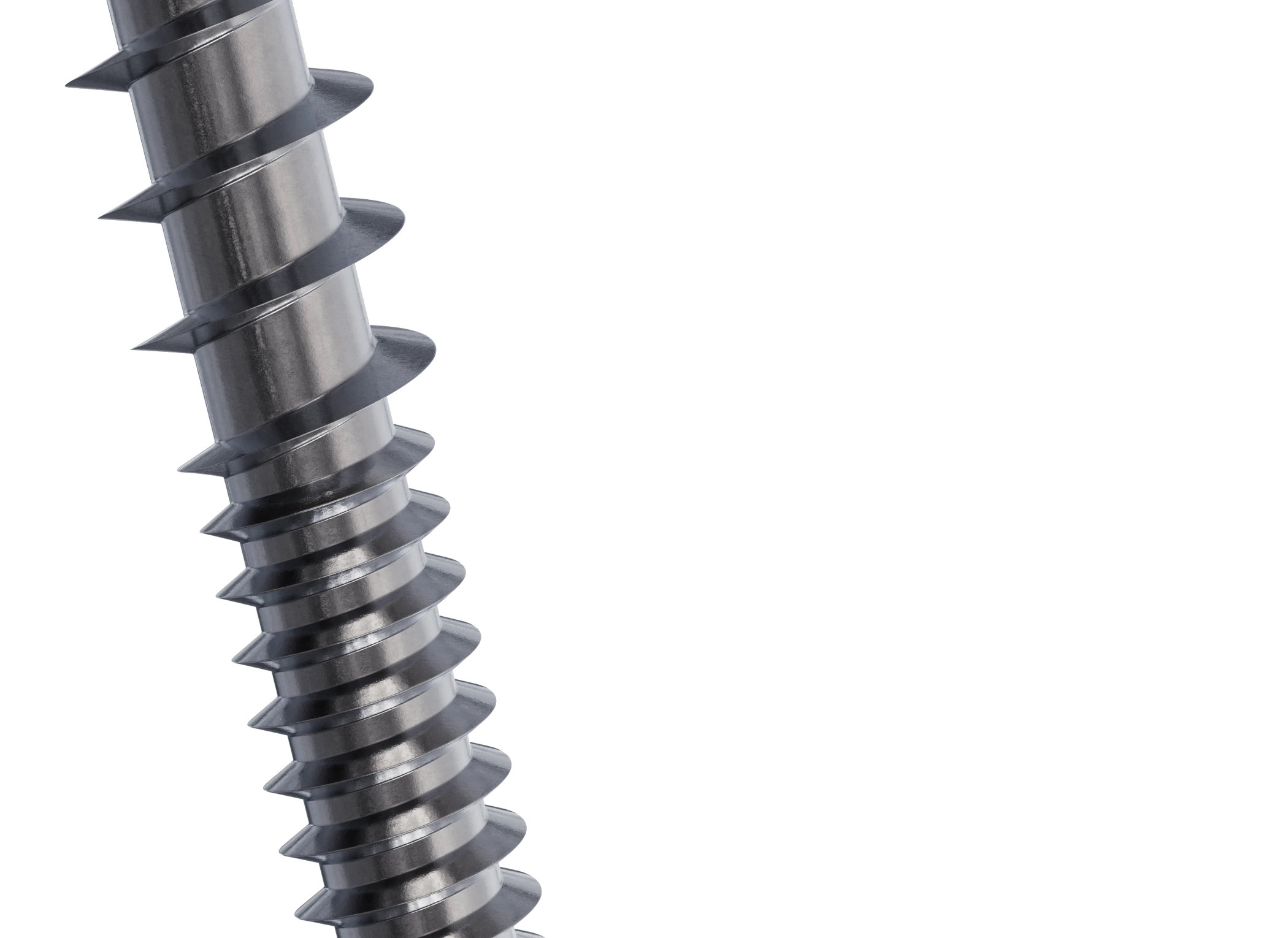

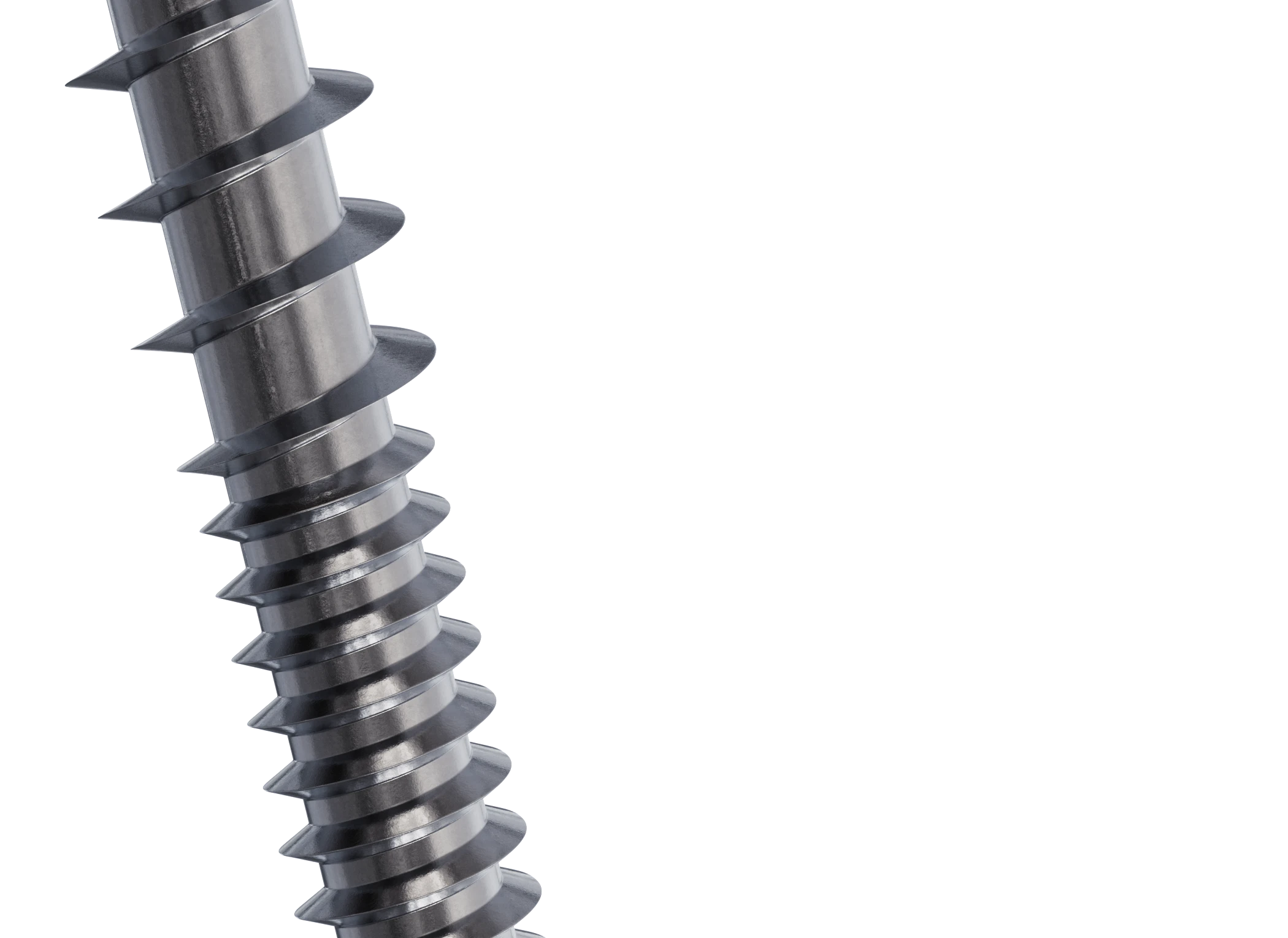

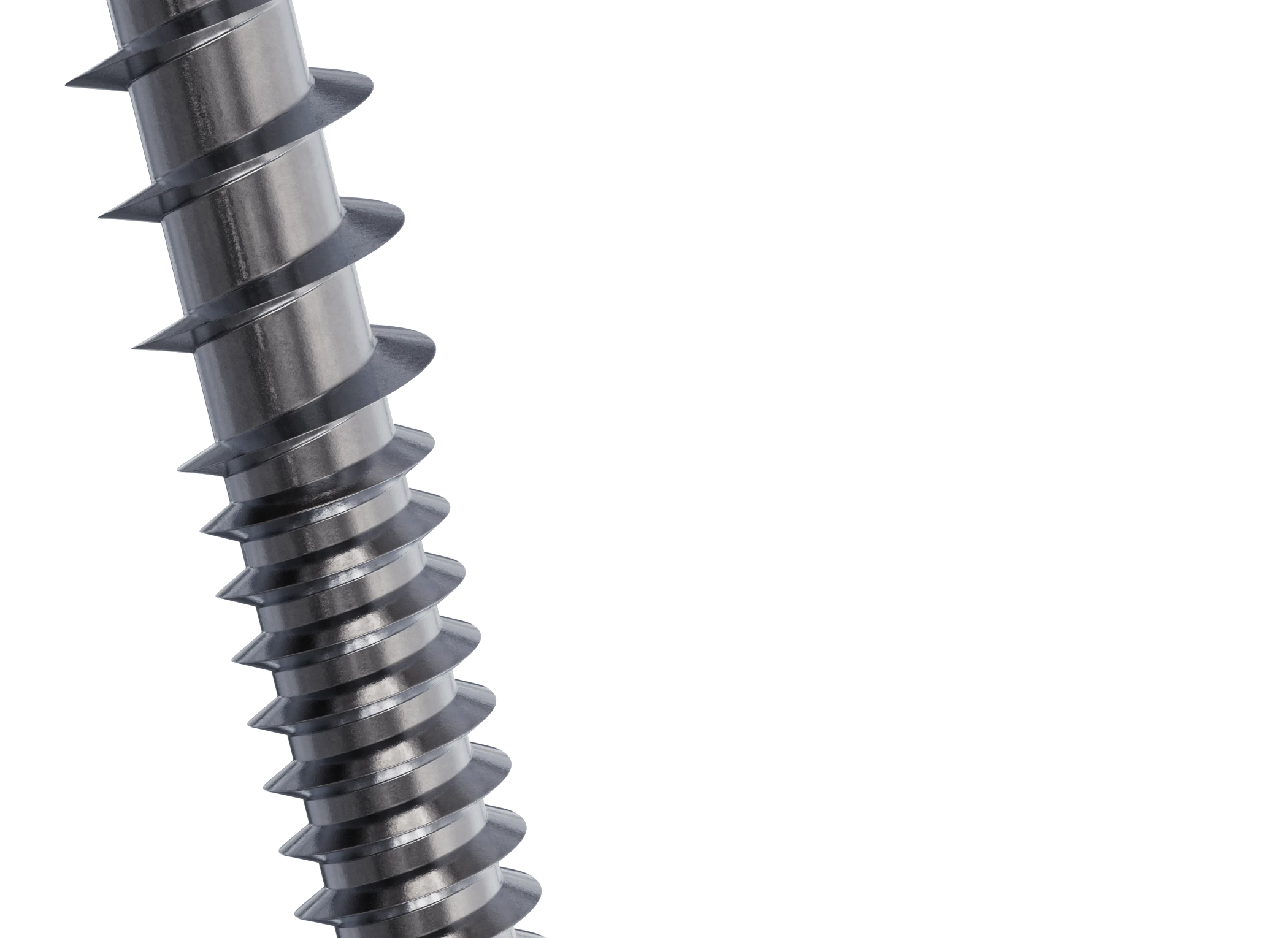

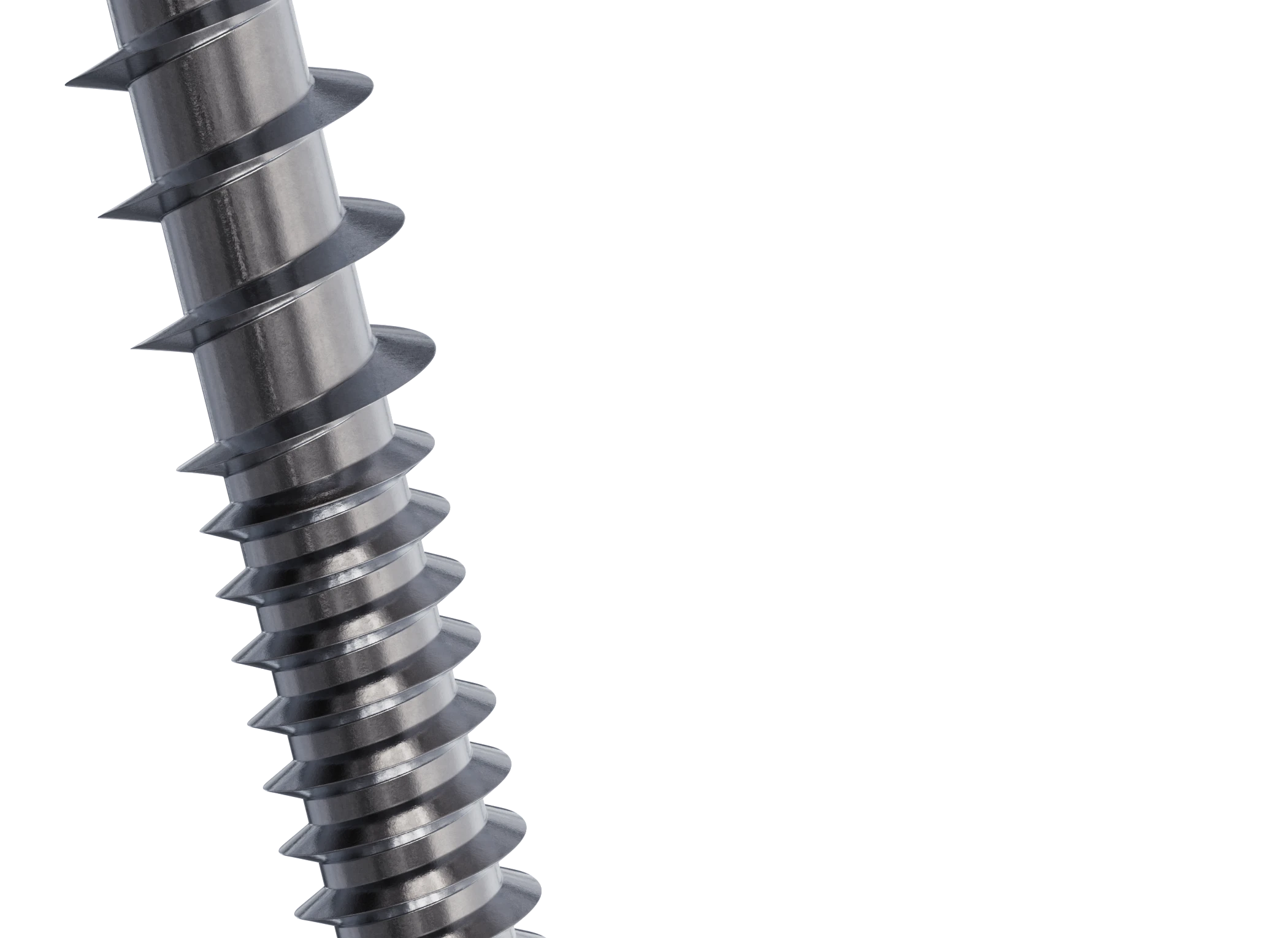

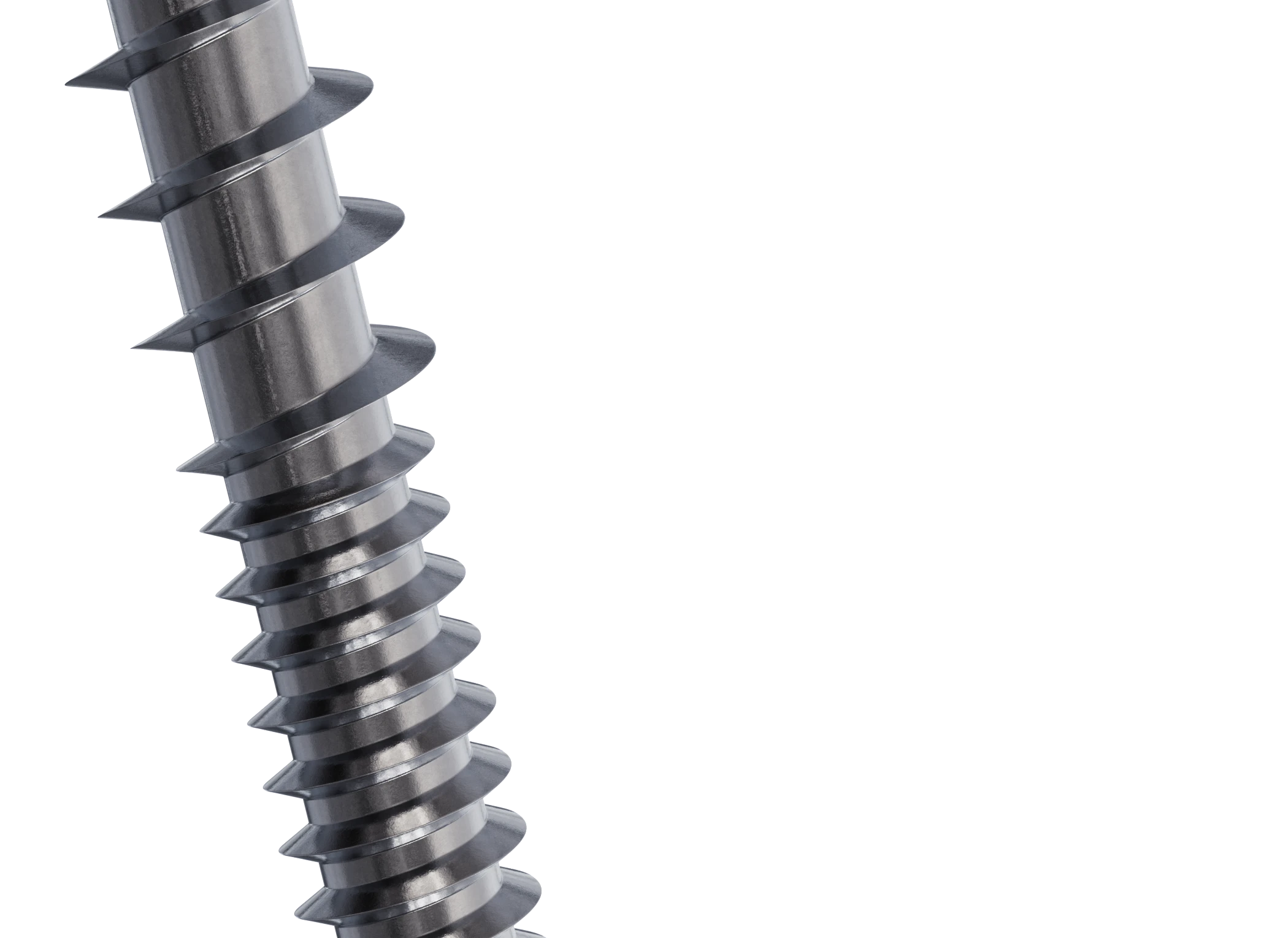

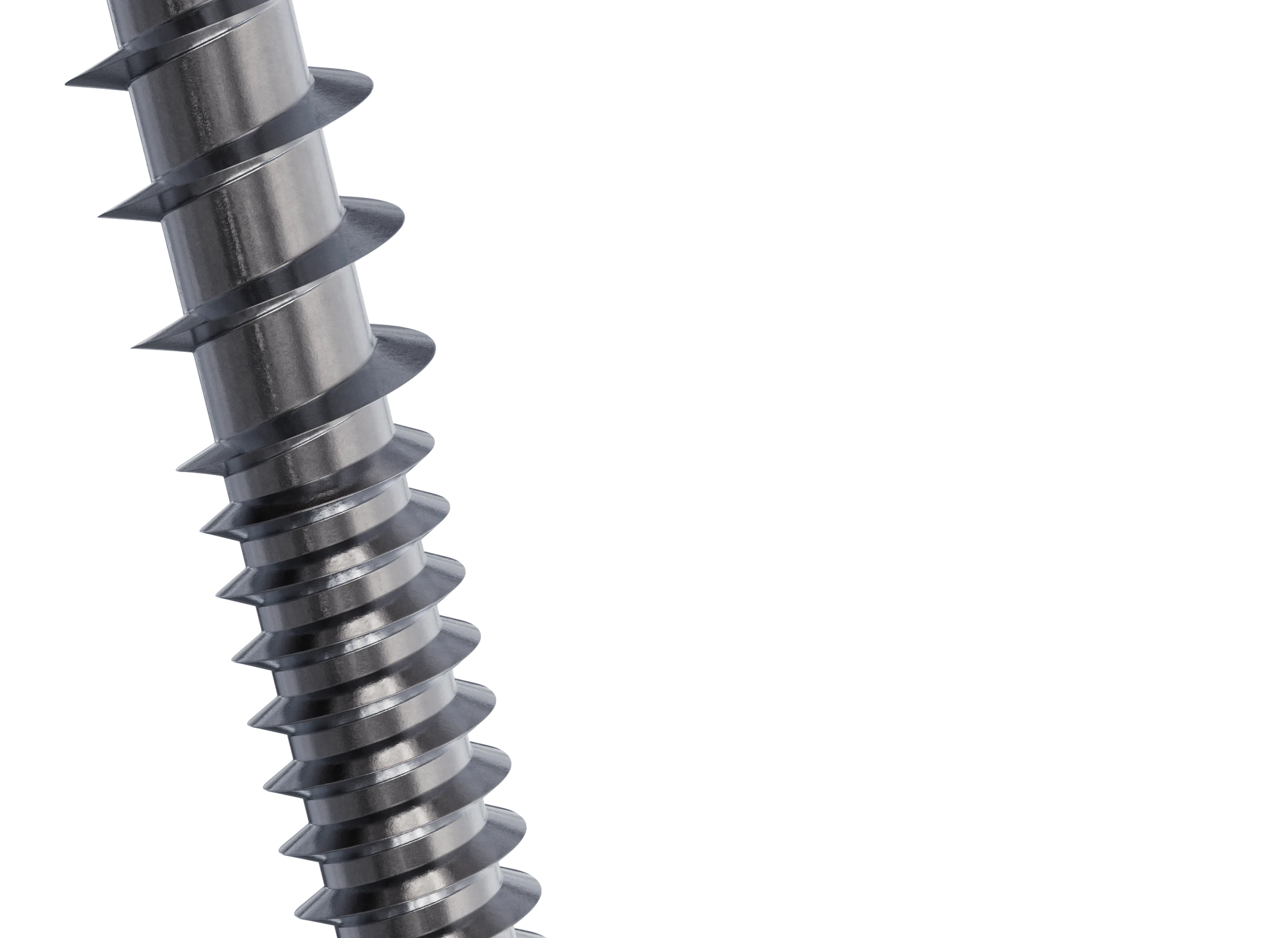

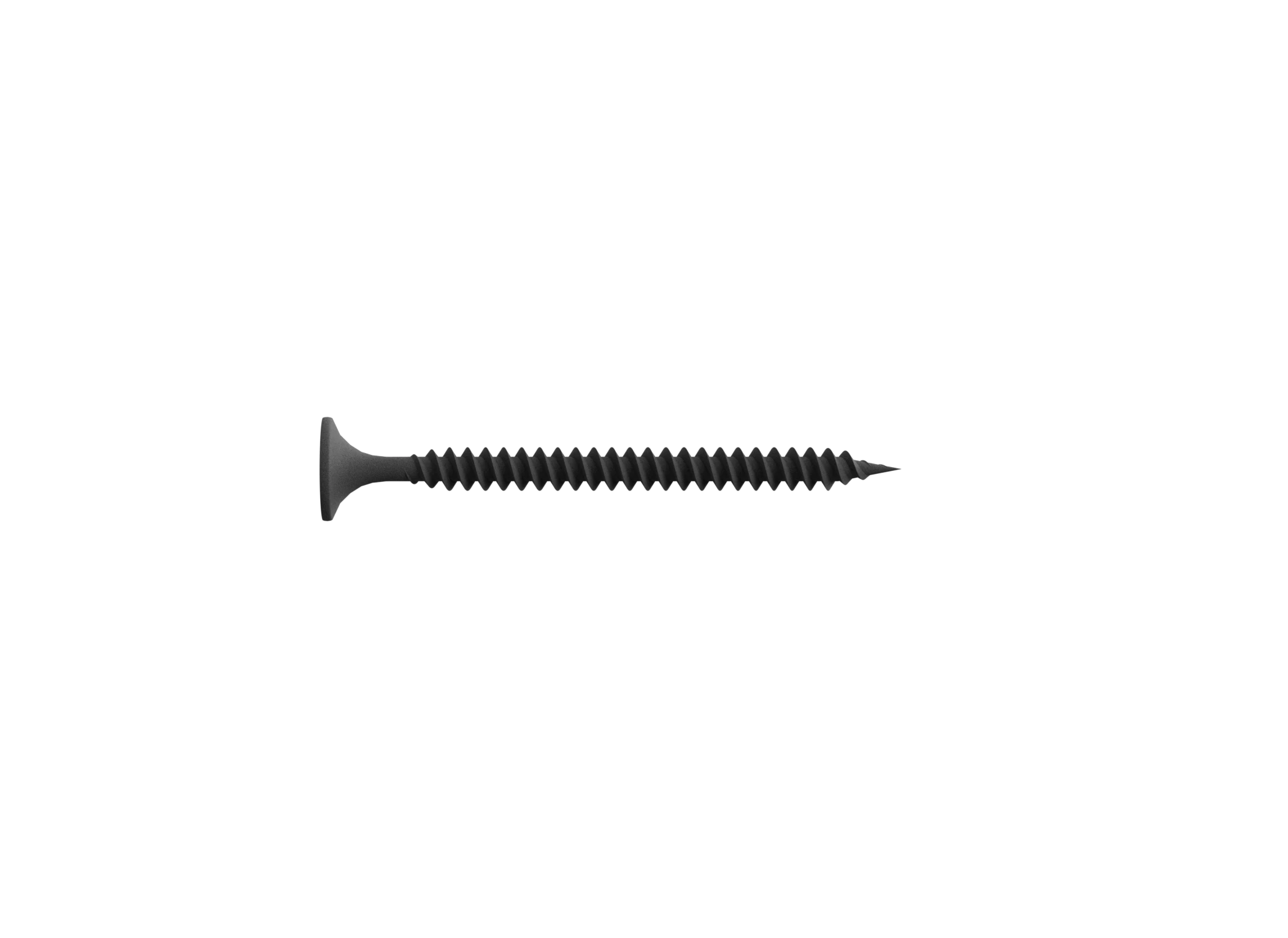

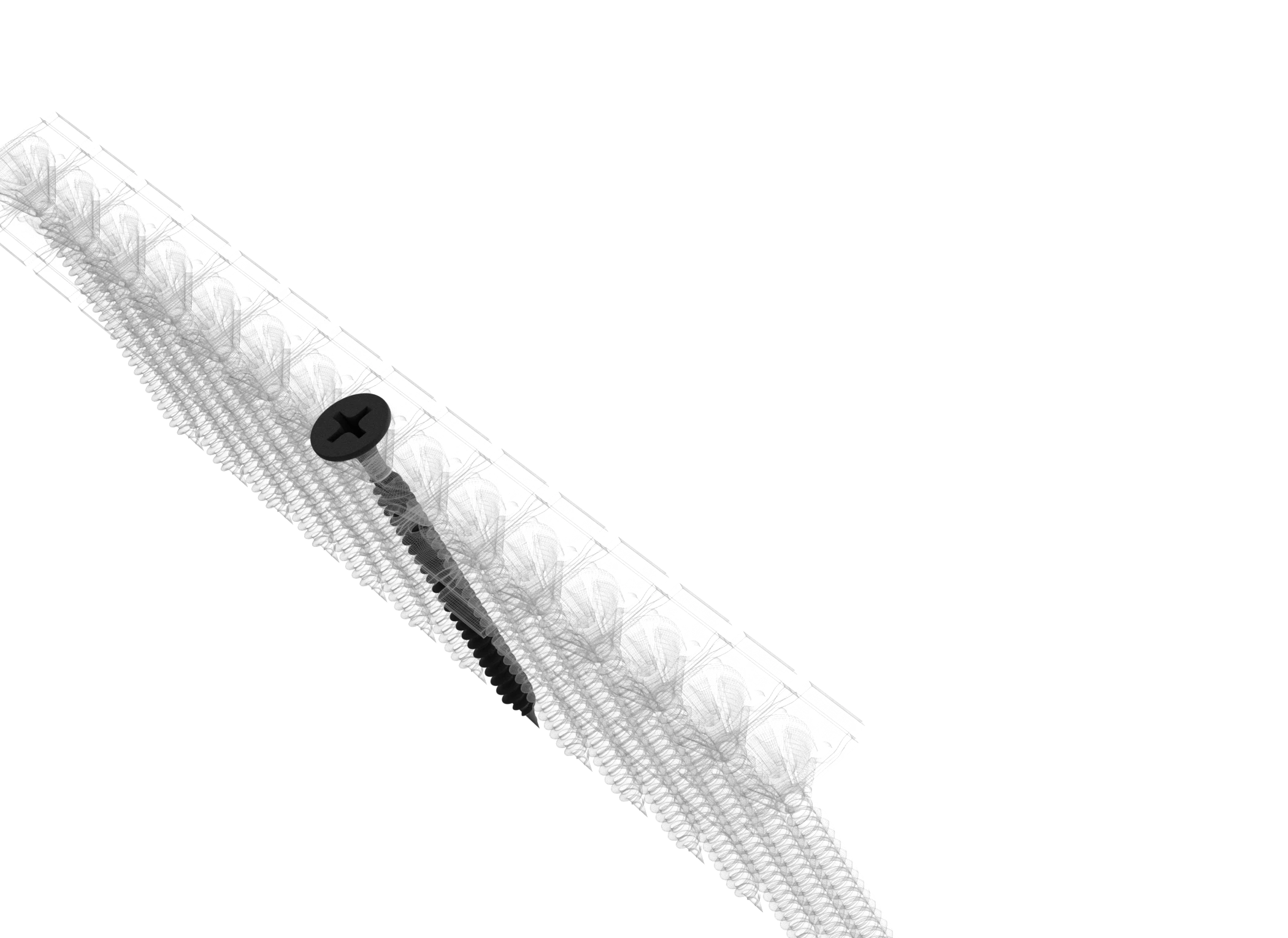

Style and Safety13PRODUCTSDrywall screws, collated drywall screws and blockframe screws86UNIQUE REFERENCESFor every fastening and work needBlockframe and Drywall screws : Eclectic safetyOur catalog offers various types of highly efficient blockframe and drywall screws for PVC and drywall, each available in different sizes, with specific and unique characteristics in terms of shape, diameter, length, thread pitch and head type.Drywall screws are designed to easily penetrate the material up to the metal profile. Most of them are phosphated and full thread, with PH bugle head. Blockframe screws are designed to be applied directly on PVC, without ruining the surface.

AREAS OF USEBlockframe and drywall screws are extremely versatile and are used in a wide range of sectors depending on the different applications: construction, metal roofing, cladding, and industrial fixtures.CERTIFIED QUALITYThe quality of blockframe and drywall screws is crucial for their reliability. The EN14566 marking certifies compliance with standards. Laboratory tests verify strength and durability. Investing in high-quality screws is essential to ensure performance and safety.WIDE RANGEAmbrovit’s blockframe and drywall screws offer a wide range of sizes to adapt to different needs, ensuring precision and reliability, as well as a secure and durable fastening, adapting to any context up to more complex installations.

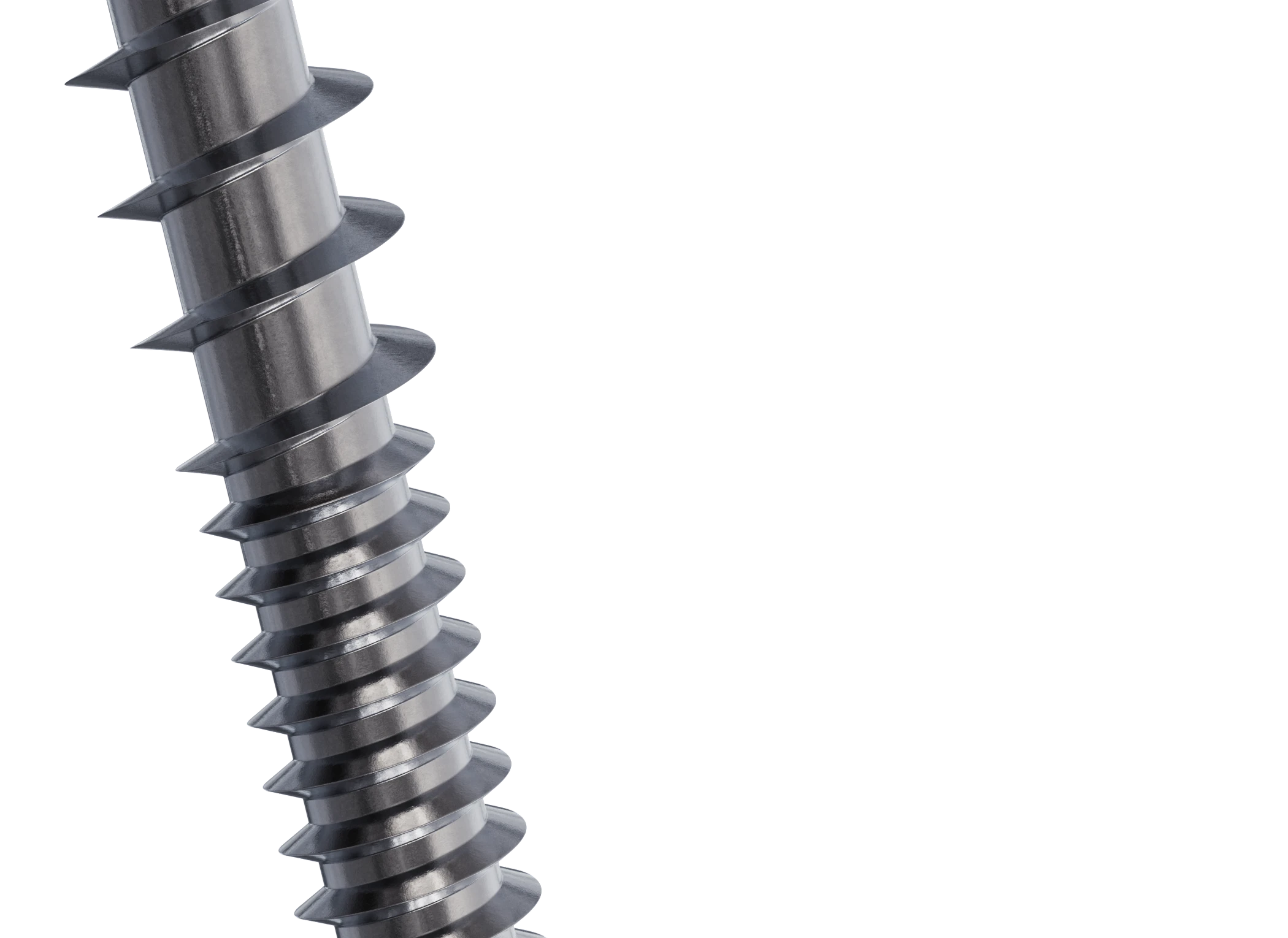

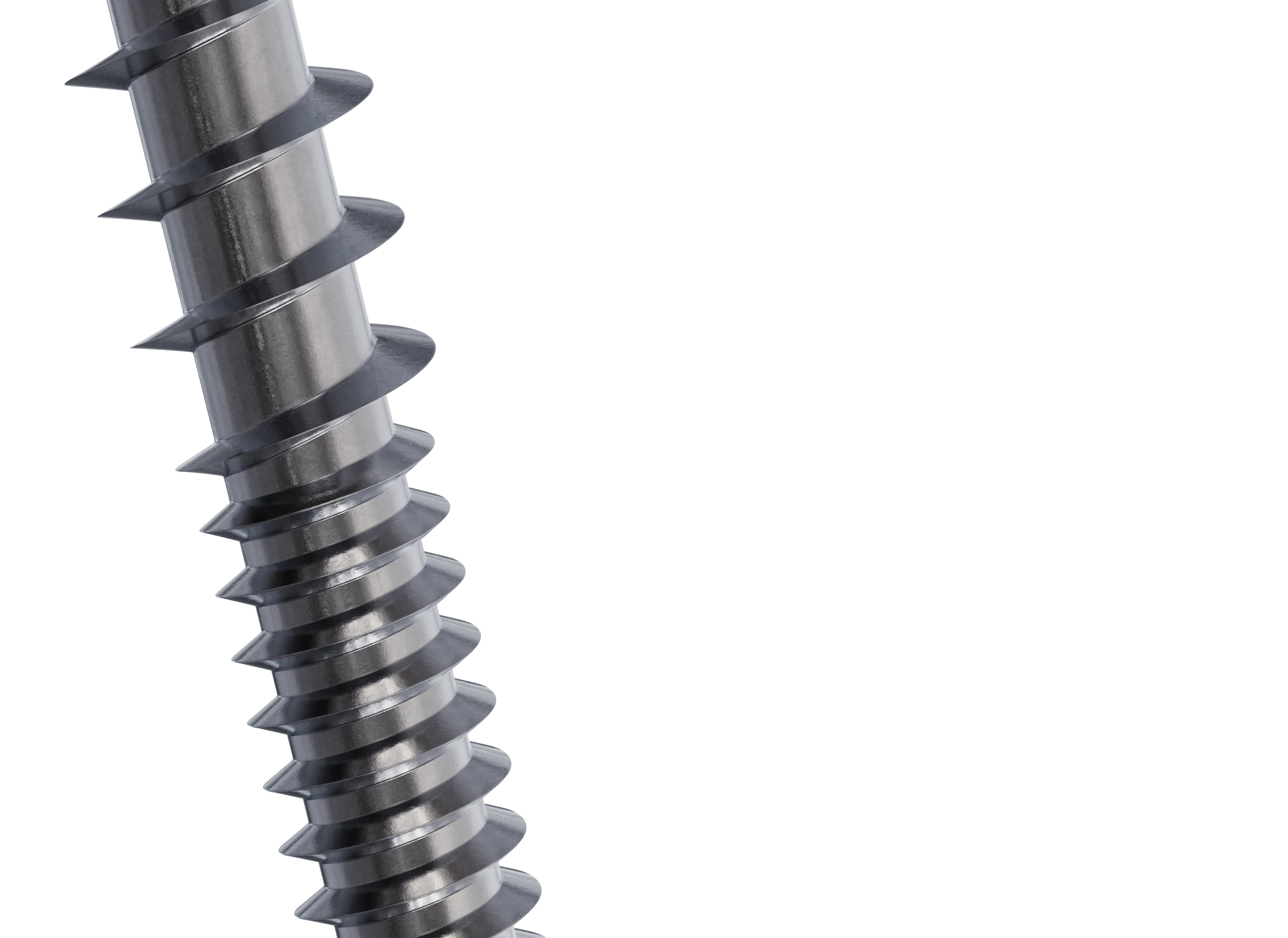

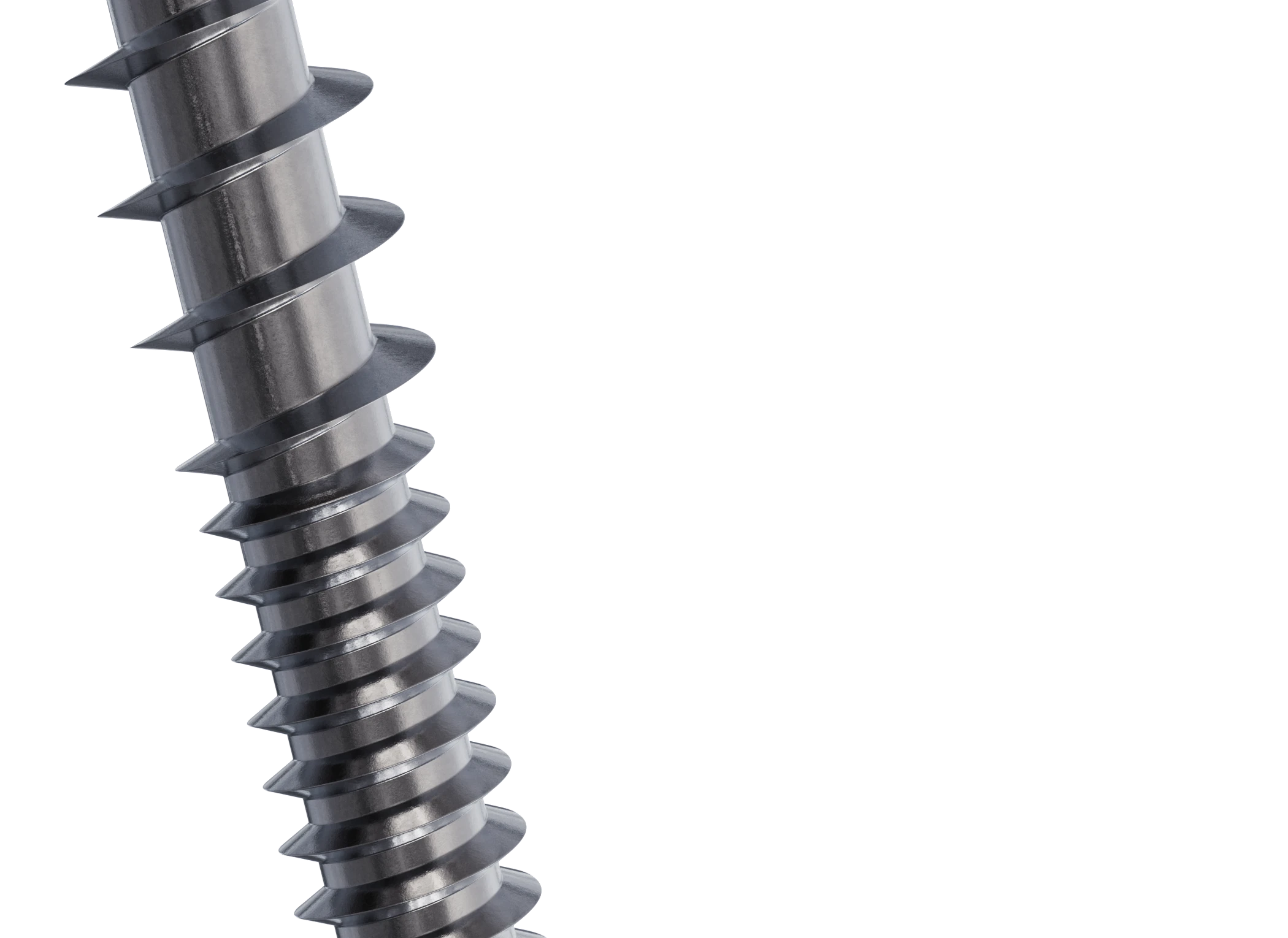

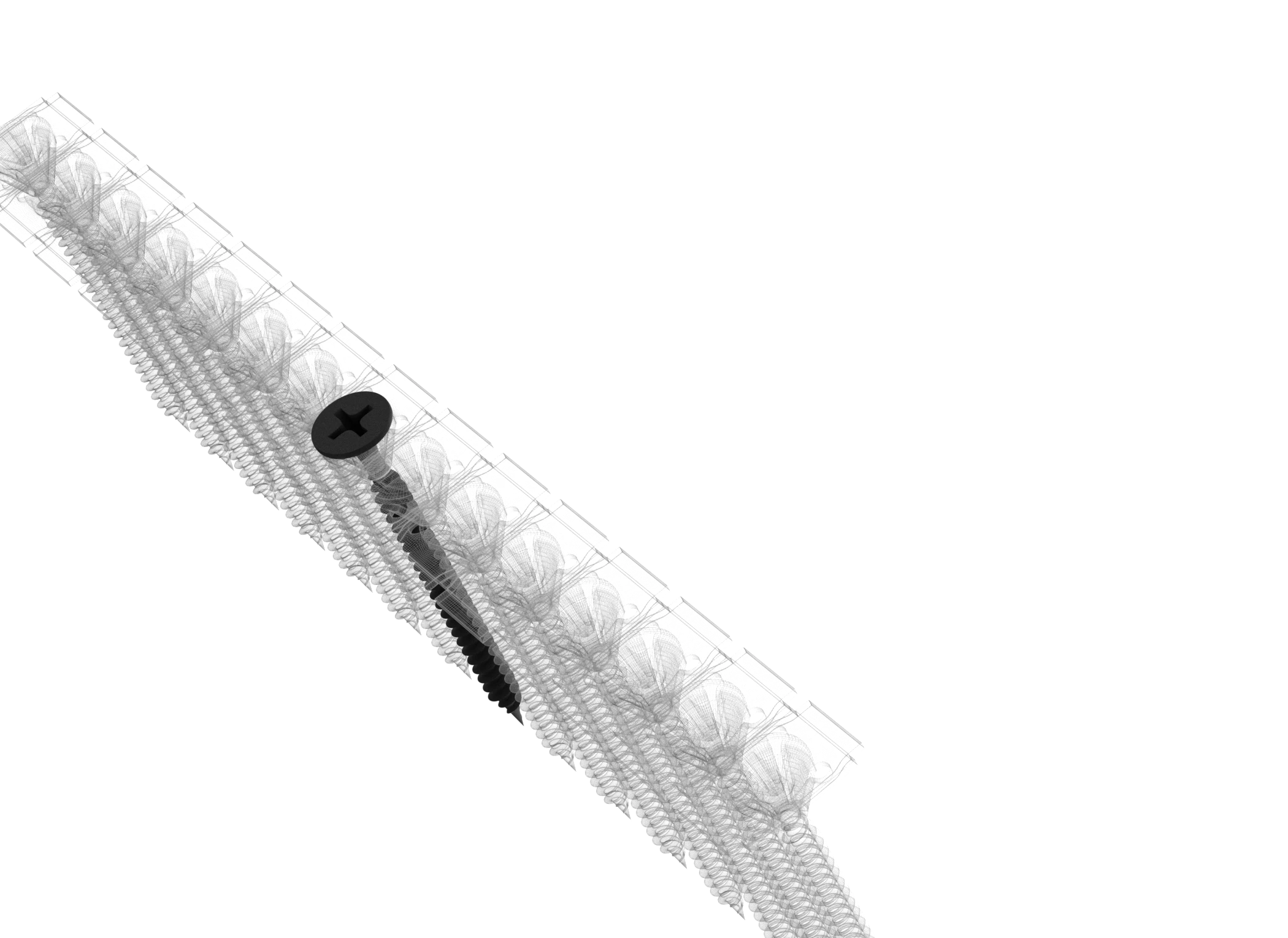

TWO DIFFERENT THREADSThe double-threaded screw features two parallel threads along the shaft, providing greater stability and strength compared to single-threaded screws. This solution allows for faster screwing, making these screws effective and efficient for multiple uses.2+Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

TWO DIFFERENT THREADSThe double-threaded screw features two parallel threads along the shaft, providing greater stability and strength compared to single-threaded screws. This solution allows for faster screwing, making these screws effective and efficient for multiple uses.2+Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

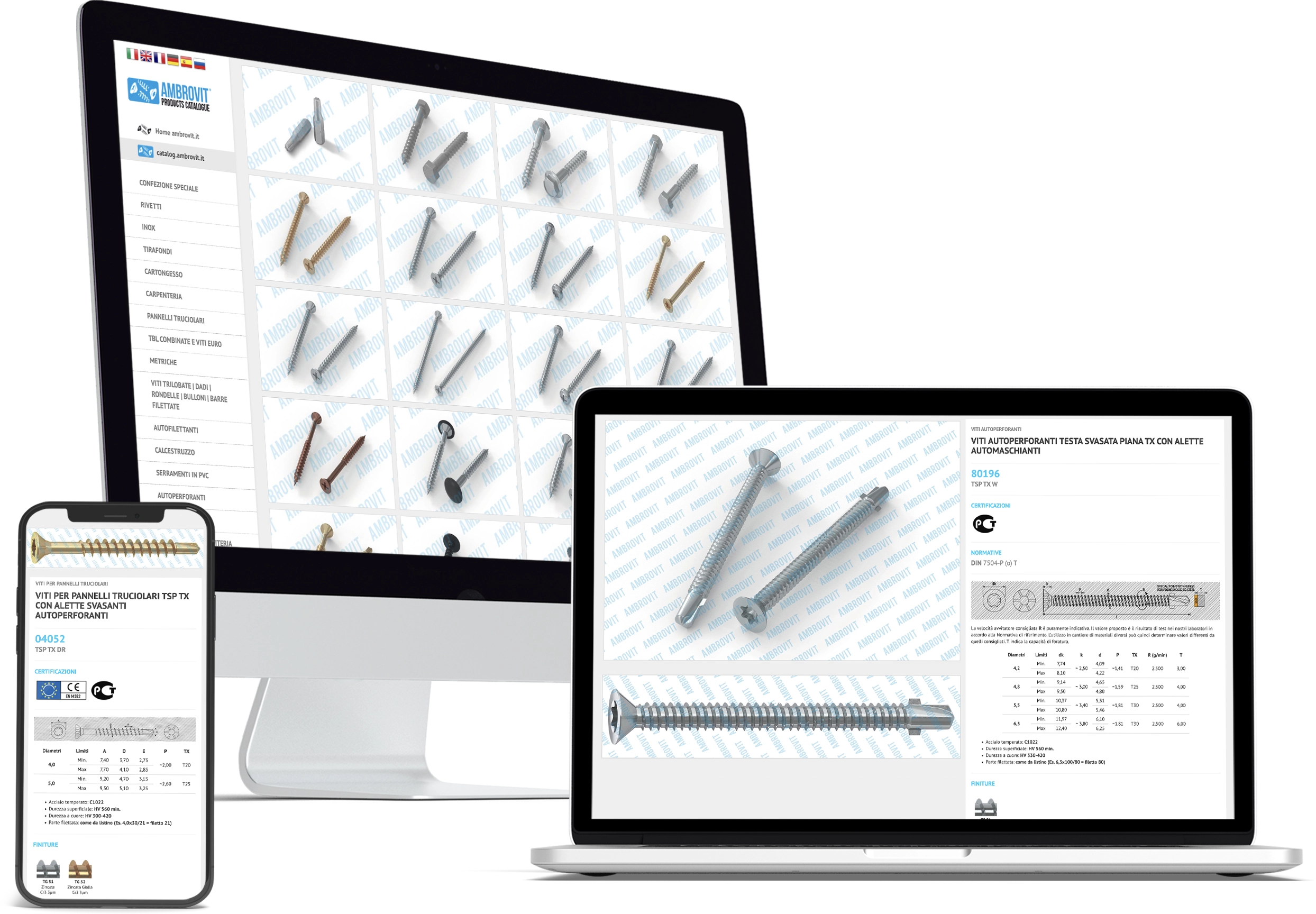

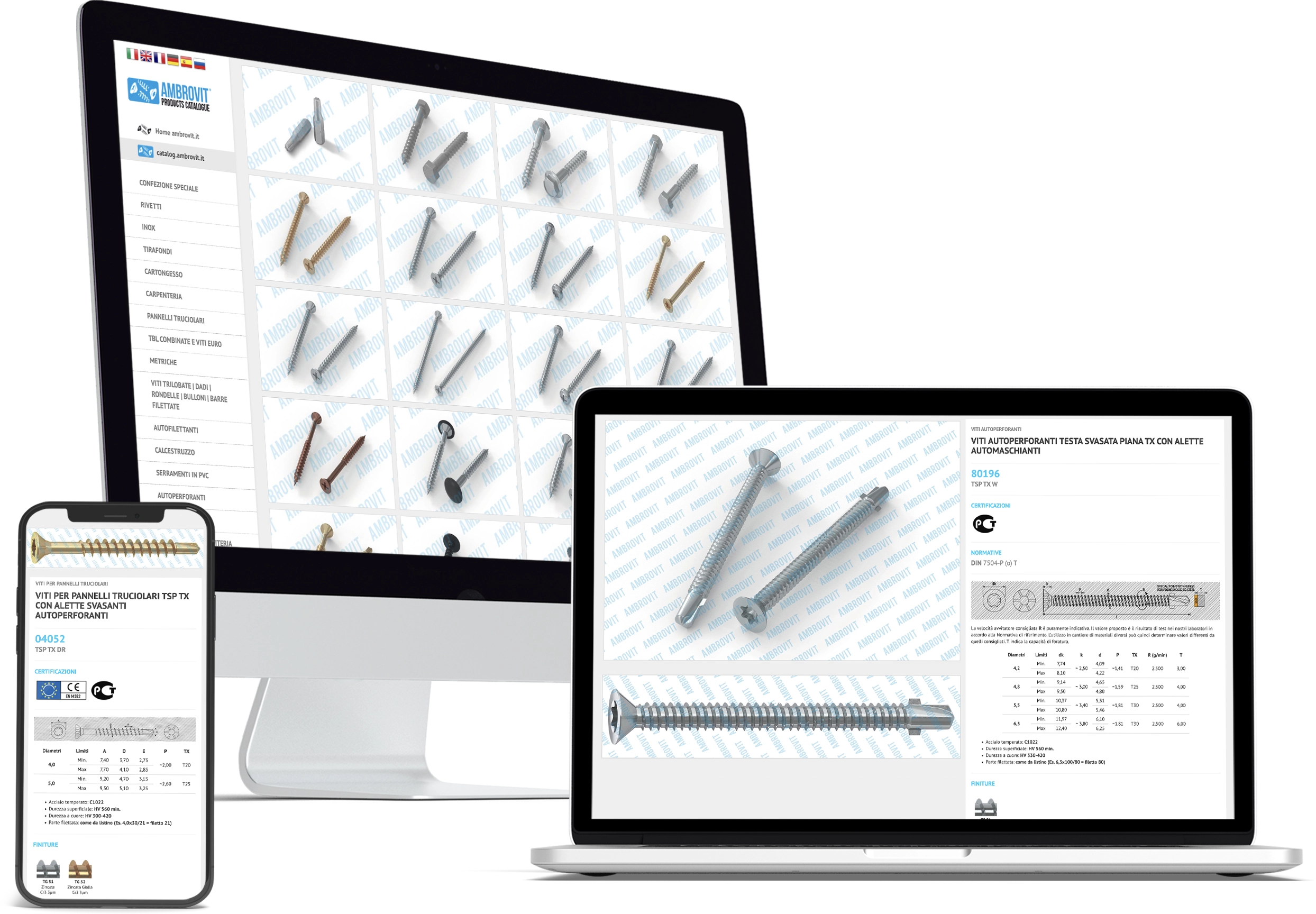

Discover it all on our online catalog.

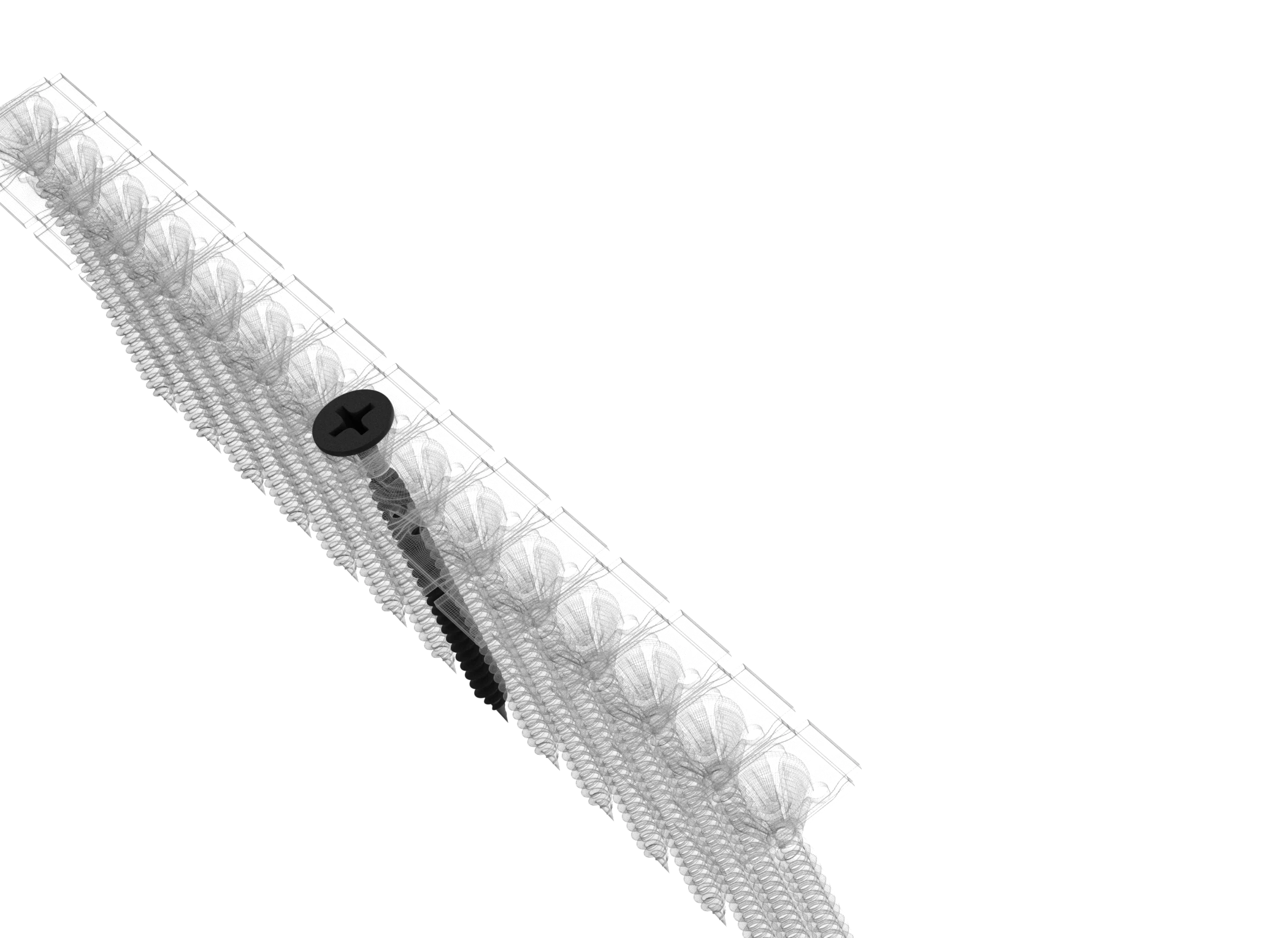

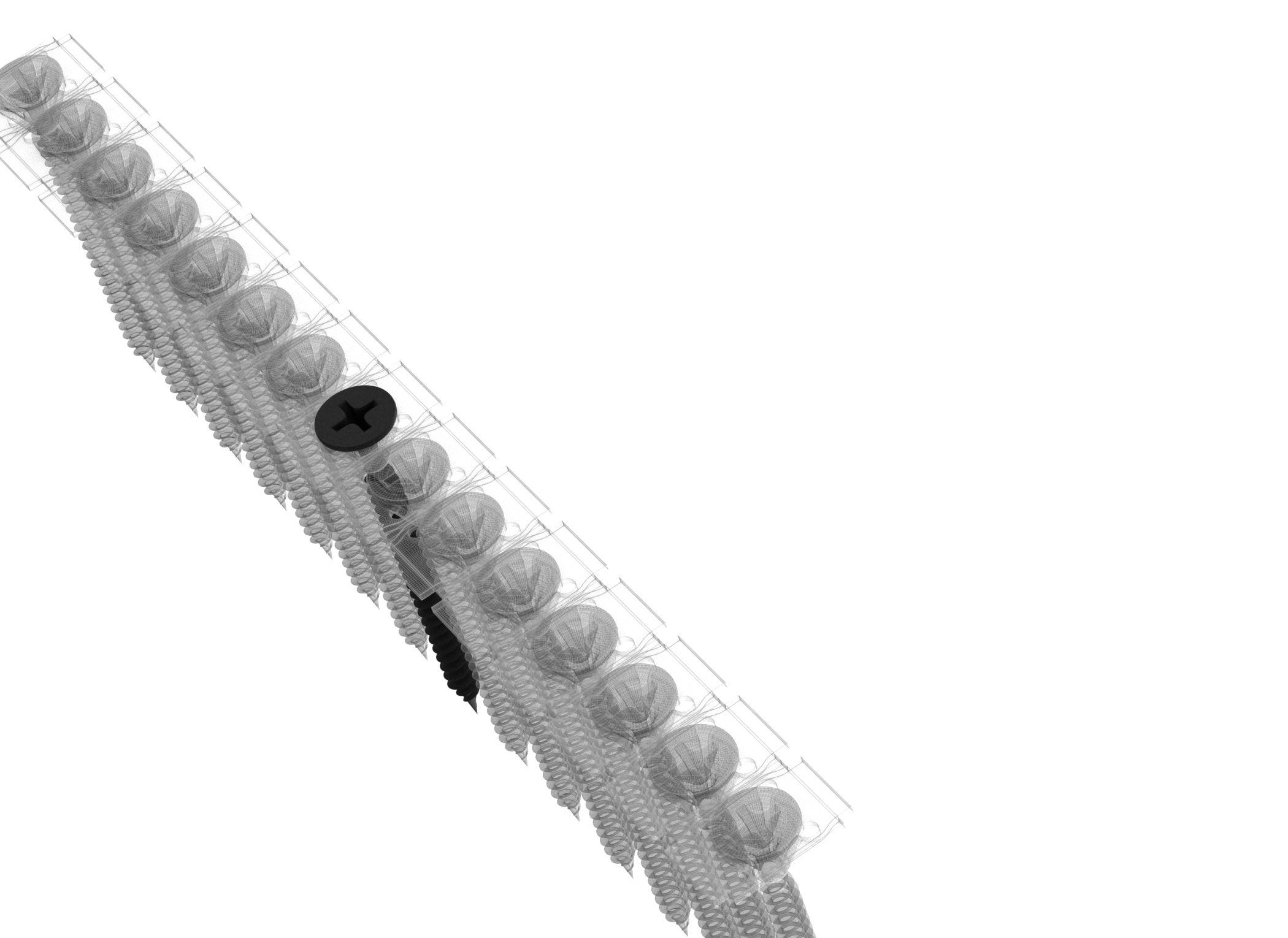

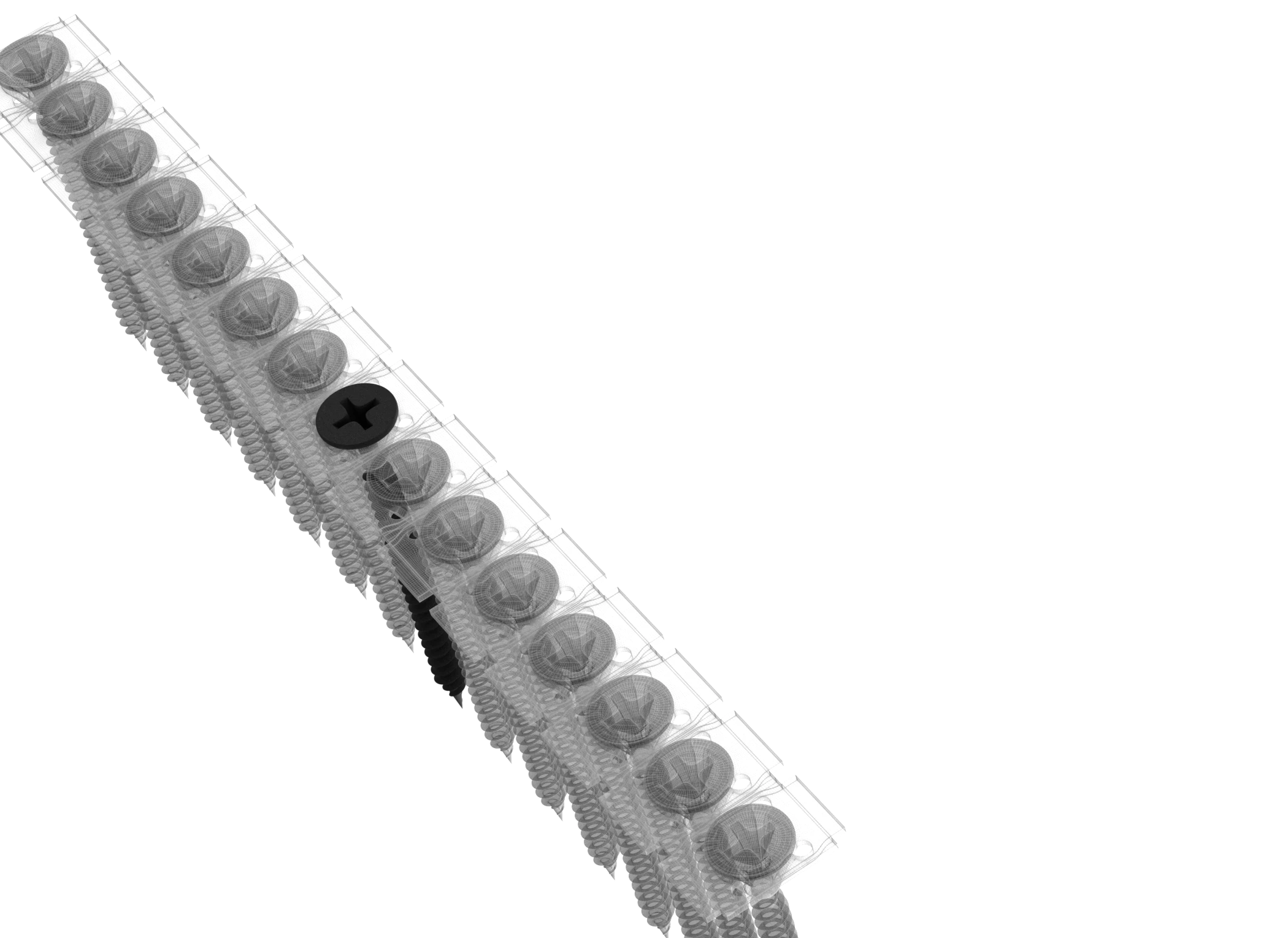

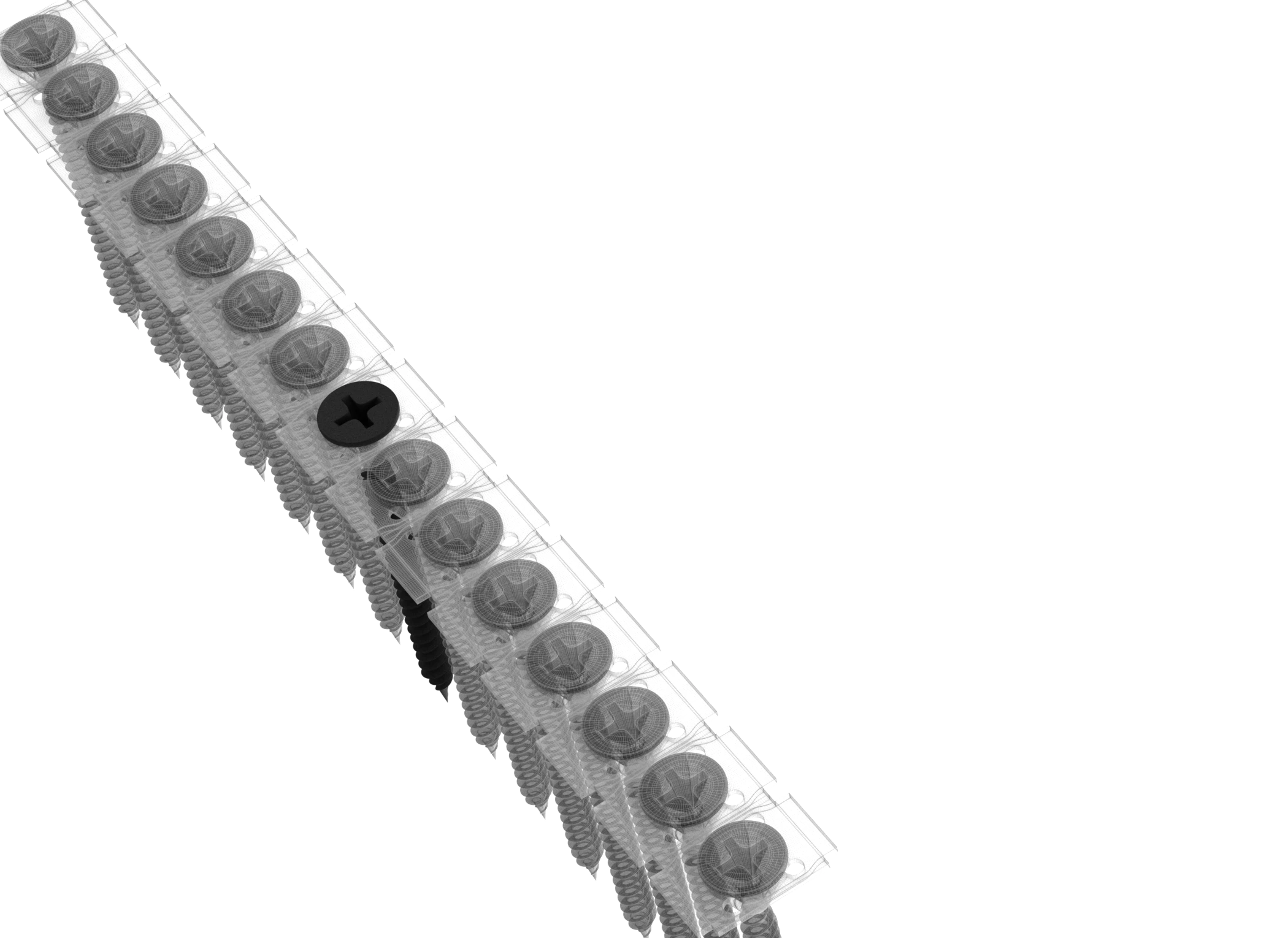

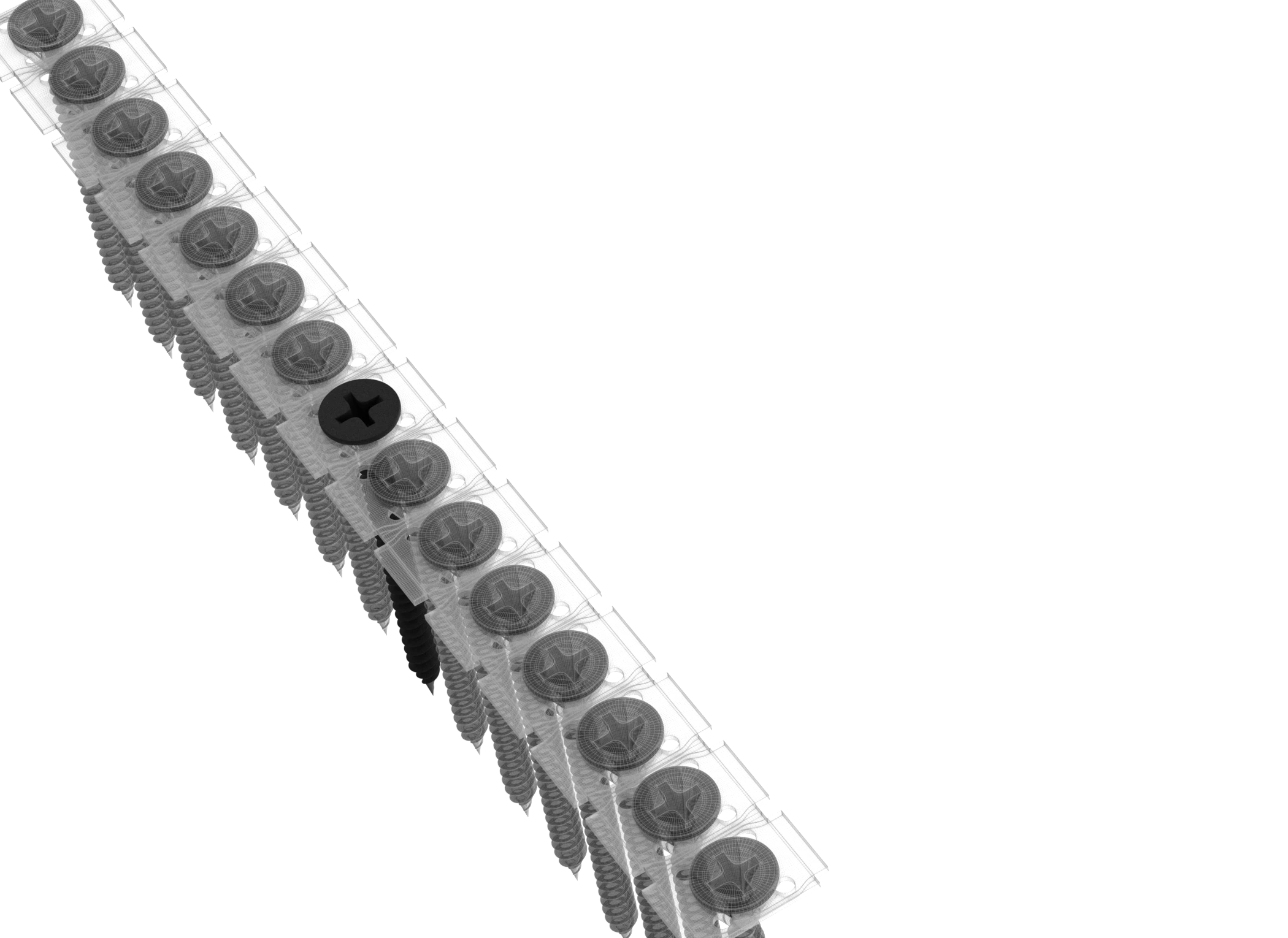

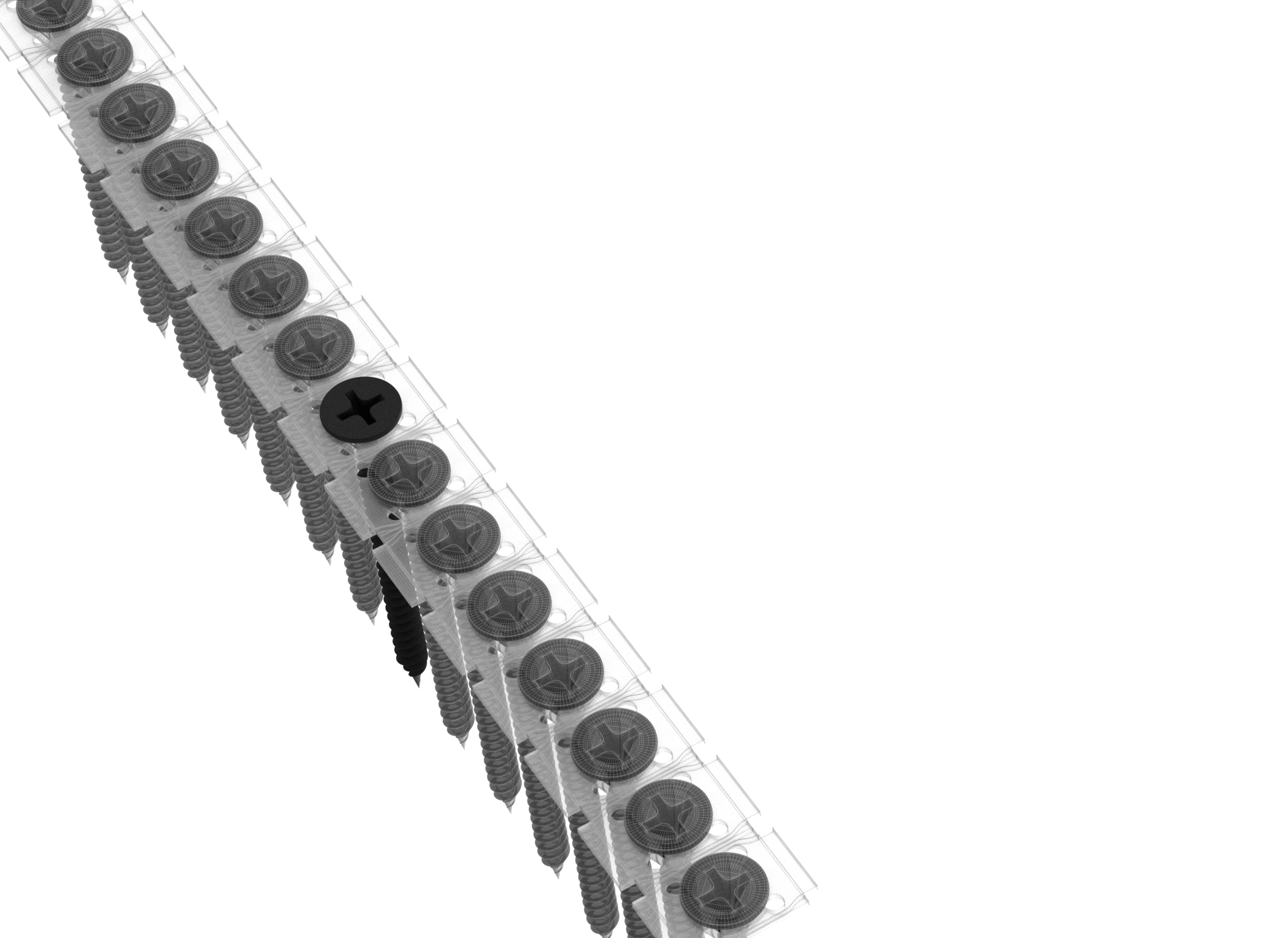

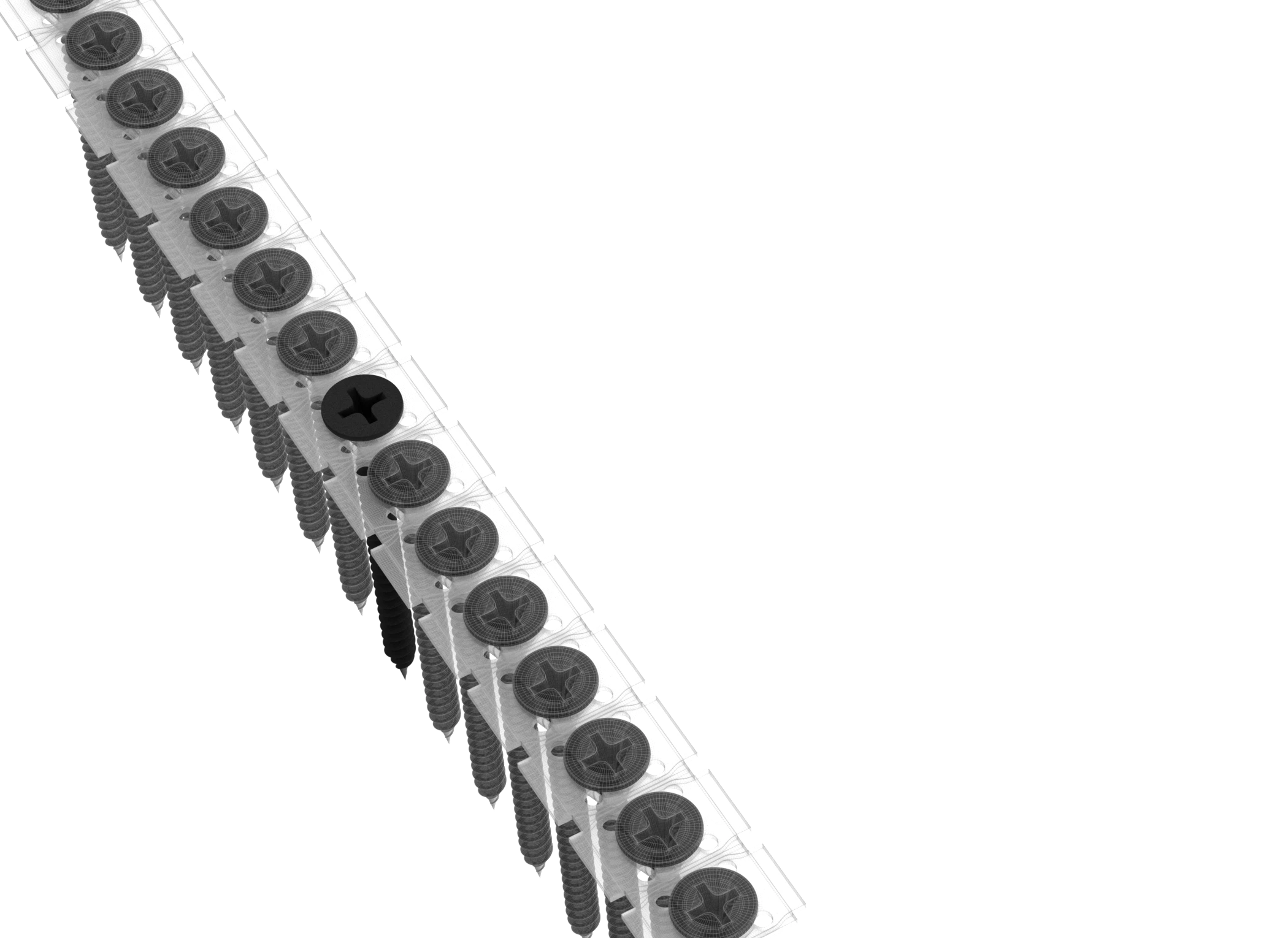

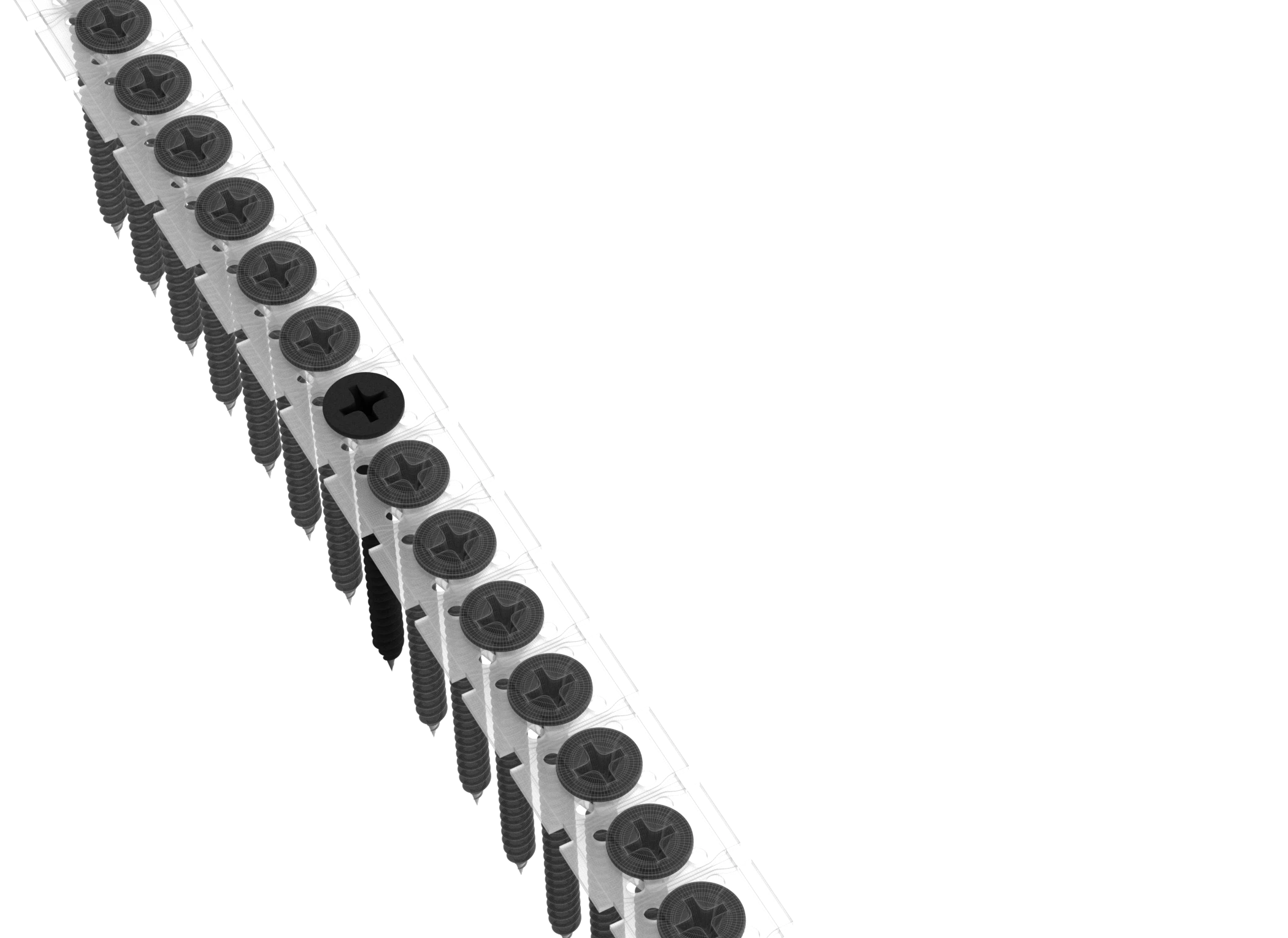

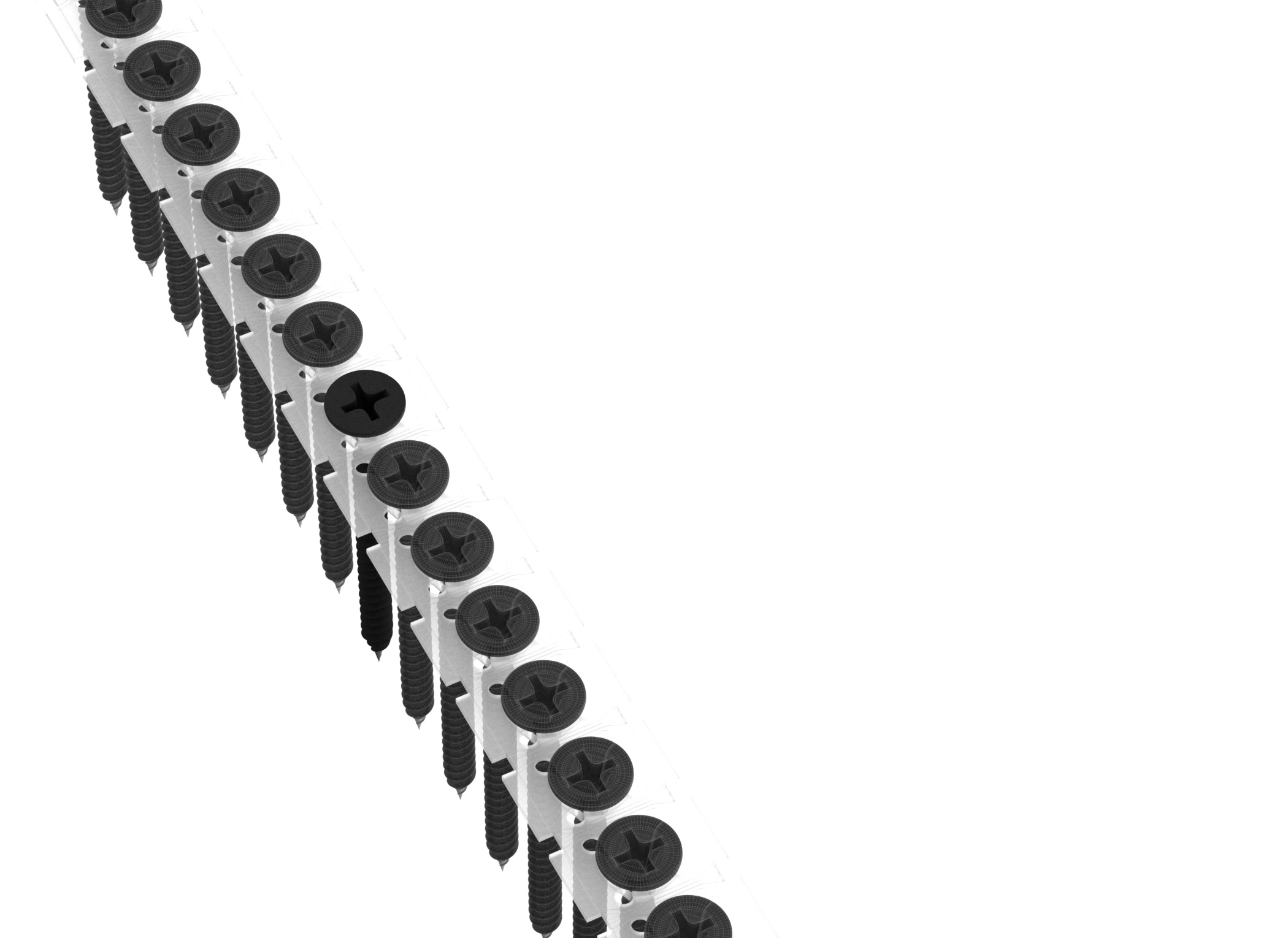

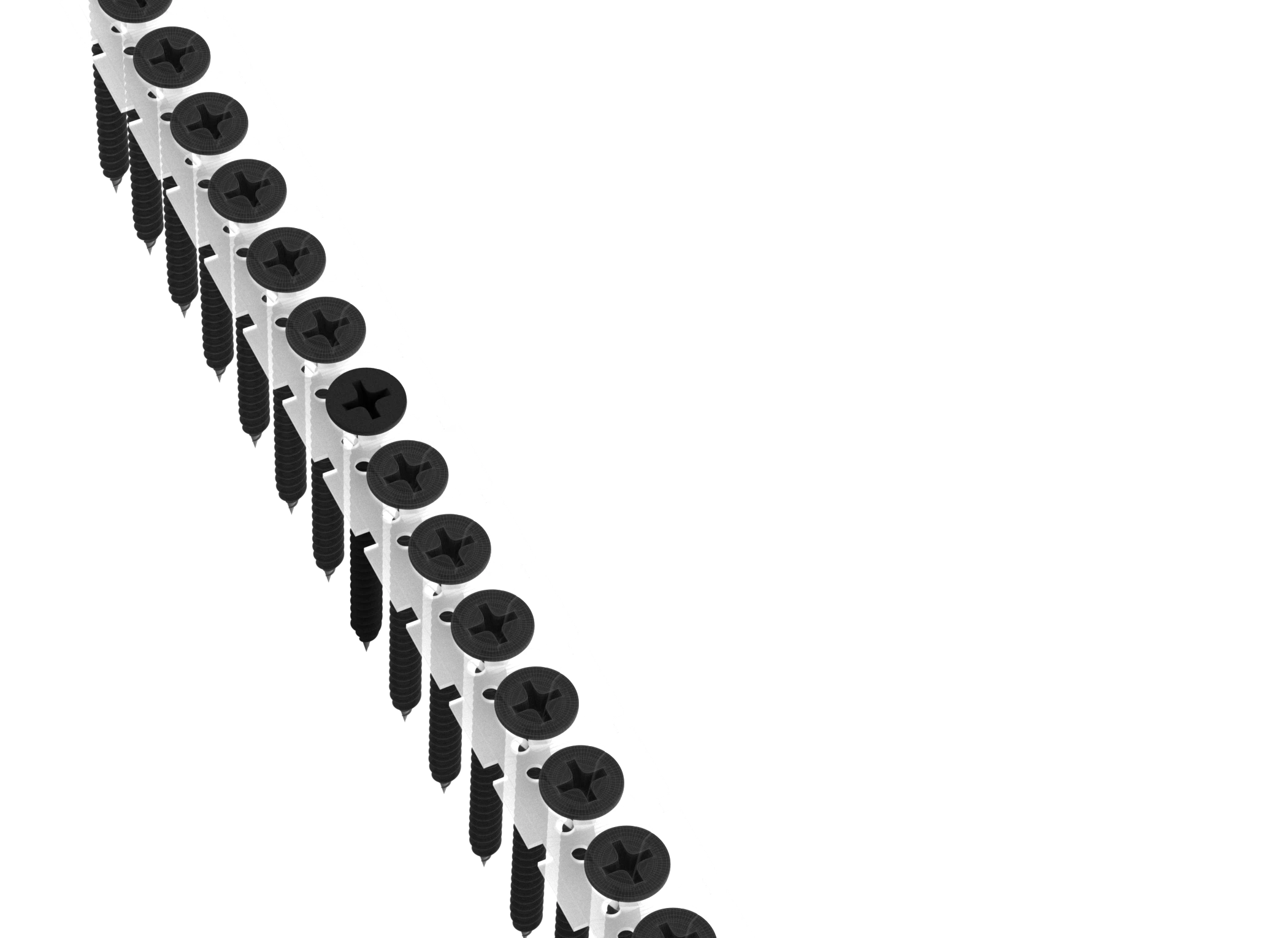

COLLATED DRYWALL SCREWSCollated screws are specially designed to make installation faster and easier. The risk of jamming of the electric screwdriver is avoided, facilitating the work.4Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

COLLATED DRYWALL SCREWSCollated screws are specially designed to make installation faster and easier. The risk of jamming of the electric screwdriver is avoided, facilitating the work.4Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

Discover it all on our online catalog.Every product is meticulously designed:

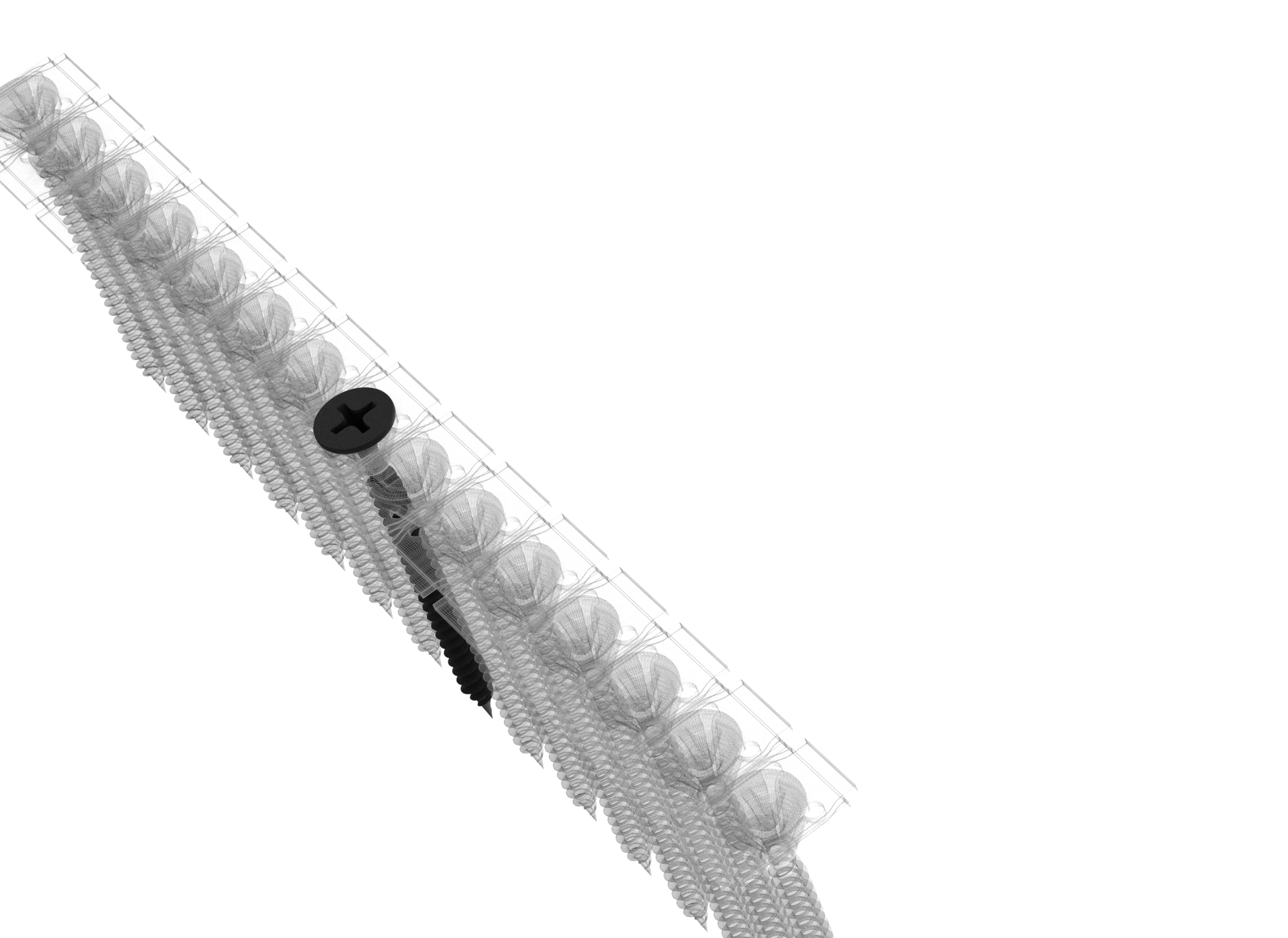

from head to tipDiscover our wide range of highly performing blockframe and drywall screws, all available in different sizes. Bugle head

Bugle headThis profile is designed to avoid the panel from breaking or sticking out.

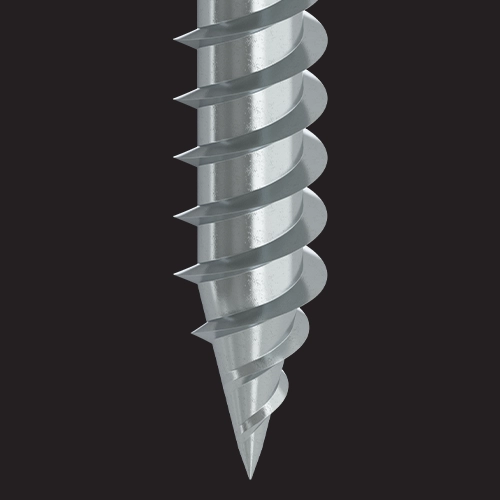

Two-start thread

Two-start threadMultiple-start screws are designed to achieve large pitches without excessively lightening the core, which would compromise the mechanical strength of the screw itself.

Multi-fins

Multi-finsA finned screw is a standard element in mechanical engineering for manual adjustment functions. It is used as a fastening element in both internal and external parts.

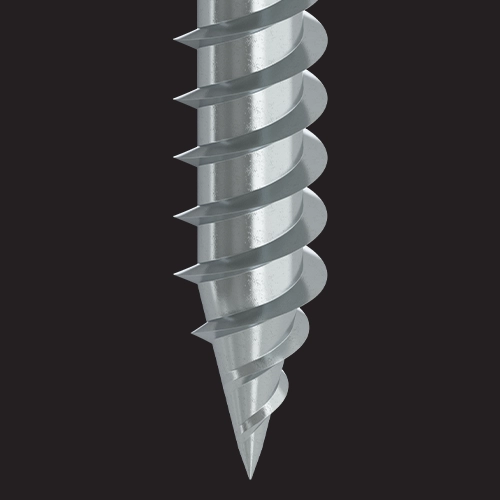

Self-drilling tip

Self-drilling tipThe self-drilling tip is particularly used for fastening to malleable materials, such as drywall. It provides speed of fastening and greater grip even with shallower holes.

Guide to the fastener profilesThe transmission of force to the screw occurs through geometric coupling; therefore, each screw requires a counterpart suitable for its profile, in the form of a screwdriver, an hex key, or an insert. Here are the most common, from the classic profile to the most innovative ones.

TORXScrew with a head characterized by a six-pointed star-shaped recess: TX wafer head, TX hexagon washer head, TX truss head, TX cylinder head, TX flat head, TX truss washer head.POZIScrew with a crosshead featuring 4 integrated slots, similar to an asterisk: PZ flat – head, PZ pan head, PZ raised oval head, PZ and slotted combination truss head, PZ wafer head, PZ and slotted wafer head, PZ and slotted combination wafer head, PZ and slotted combination truss head.PHILLIPSScrew with an engraved crosshead, offering a good combination of stability and ease of use: PH bugle head, PH flat head, PH pan head, PH wafer head, PH truss washer head.HEXAGONHexagonal head screw with six sides forming between them an angle of 120°: Hexagonal head, hexagonal head with flange, hexagon flat washer head, hexagon socket truss head, hexagon socket cylinder head, hexagon countersunk socket flat head.SQUAREScrew with an engraved square drive, often used in industrial settings: square drive pan head, mushroom head square neck.SLOTScrew with an engraving in the form of a straight slot: slotted flat head, slotted raised oval head, slotted cheese head. Find the best deal for your businessExplore our online catalog, with 15 different families of screws, and discover a wide range of options to meet your specific fastening needs.NEW MILESTONES

Find the best deal for your businessExplore our online catalog, with 15 different families of screws, and discover a wide range of options to meet your specific fastening needs.NEW MILESTONES

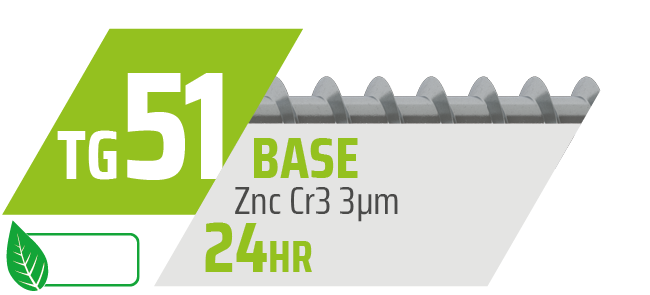

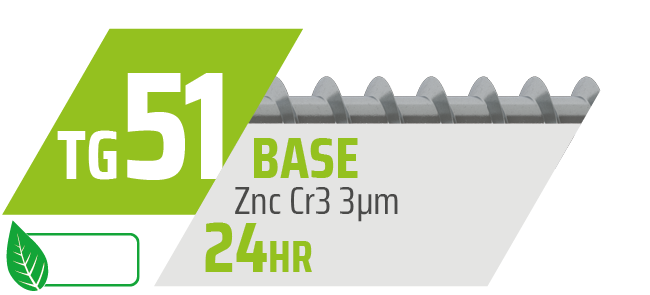

OF EXCELLENCEQuality is the vector that makes our company stand out in a constantly evolving market. Our main mission is to achieve new levels of excellence in every reference sector, consistently expanding our range to meet the demands of an increasingly discerning professional clientele. When quality is involved there is no place for compromise, and the proof is in all of the products available in our catalog.FINISHES: PROTECTION AND CUSTOMIZATIONThe finishes of screws can vary significantly in terms of strength and aesthetic appearance, offering options to meet specific needs. Protective finishes are designed to shield screws from corrosion and wear ad tear, providing them with greater durability over time, making them ideal for applications in hostile environments or exposed to atmospheric agents. Aesthetic finishes are crafted to enhance the appearance of screws. They offer a more appealing smooth and shiny surface. They are often used in visible applications where appearance makes a difference. The selection of screw finishes is crucial to ensure they can reliably perform their function and seamlessly integrate into the overall project’s aesthetic appearance.

The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.THE QUALITY

The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.THE QUALITY

OF OUR SCREWSAmbrovit’s screw certifications are a fundamental to ensure the quality and safety of the products. Ambrovit is committed to meeting the highest production standards and providing screws that meet customer needs. These certifications testify to the company’s dedication to quality, safety, and compliance with regulations throughout the production process. Customers can therefore have confidence in using Ambrovit screws for their requirements, knowing that they meet rigorous standards and are suitable for a wide range of applications.Learn more about our products quality:AMBROVIT QUALITYLearn more about our products quality:AMBROVIT QUALITYWHERE EVERYTHING

IS CERTIFIEDDuring the years quality has become a pervasive value that involves every sector and department of the company, leading to the company obtaining ISO 9001 certification for the Quality Management System in 2011. Most products are equipped with varied certifications based on their type and intended use. Additional quality control tests are conducted internally on-site in collaboration with Uni Trento.

Ambrovit has achieved ISO 9001 certification, a recognition of quality and safety. To attain this certification, the company must demonstrate adherence to criteria such as advanced quality control, regulatory compliance, use of high-quality materials, product safety, and environmental commitment. Sustaining the certification demands a continuous dedication to improvement. This seal of approval serves as a robust indicator of reliability and quality, capable of bolstering customer confidence.

SCOPRI DI PIÙTÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures.

SCOPRI DI PIÙTÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures.

ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MOREETA (European Technical Assessment) certification is a European process of technical evaluation that assesses and approves the suitability of construction products in compliance with European regulations. This procedure is particularly relevant for the building and construction industry. The ETA certification process involves a comprehensive technical assessment by notified bodies, which examine products based on technical requirements and performance criteria.

SCOPRI DI PIÙETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

SCOPRI DI PIÙETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

Ambrovit proudly holds the ETA 16/0381 Certification for its entire range of carpentry screws, the ETA 18/1065 Option 1 Certification for anchoring screws in concrete, and the Post R Certificate of Conformity and Safety.

Once an ETA certification is obtained, products can be marketed in all European Union countries, facilitating their acceptance in the European market and transparently showcasing compliance with required technical standards. ETA certification is essential to ensure the quality and safety of construction products and to promote the free movement of goods within the EU.LEARN MOREBlockframe and Drywall

Style and Safety13PRODUCTSDrywall screws, collated drywall screws and blockframe screws86UNIQUE REFERENCESFor every fastening and work needBlockframe and Drywall screws : Eclectic safetyOur catalog offers various types of highly efficient blockframe and drywall screws for PVC and drywall, each available in different sizes, with specific and unique characteristics in terms of shape, diameter, length, thread pitch and head type.Drywall screws are designed to easily penetrate the material up to the metal profile. Most of them are phosphated and full thread, with PH bugle head. Blockframe screws are designed to be applied directly on PVC, without ruining the surface.

AREAS OF USEBlockframe and drywall screws are extremely versatile and are used in a wide range of sectors depending on the different applications: construction, metal roofing, cladding, and industrial fixtures.CERTIFIED QUALITYThe quality of blockframe and drywall screws is crucial for their reliability. The EN14566 marking certifies compliance with standards. Laboratory tests verify strength and durability. Investing in high-quality screws is essential to ensure performance and safety.WIDE RANGEAmbrovit’s blockframe and drywall screws offer a wide range of sizes to adapt to different needs, ensuring precision and reliability, as well as a secure and durable fastening, adapting to any context up to more complex installations. TWO DIFFERENT THREADSThe double-threaded screw features two parallel threads along the shaft, providing greater stability and strength compared to single-threaded screws. This solution allows for faster screwing, making these screws effective and efficient for multiple uses.2+Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

TWO DIFFERENT THREADSThe double-threaded screw features two parallel threads along the shaft, providing greater stability and strength compared to single-threaded screws. This solution allows for faster screwing, making these screws effective and efficient for multiple uses.2+Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

Discover it all on our online catalog. COLLATED DRYWALL SCREWSCollated screws are specially designed to make installation faster and easier. The risk of jamming of the electric screwdriver is avoided, facilitating the work.4Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

COLLATED DRYWALL SCREWSCollated screws are specially designed to make installation faster and easier. The risk of jamming of the electric screwdriver is avoided, facilitating the work.4Different references on our online catalogDISCOVER OUR OFFERMaximize the quality of your supplies choosing from our wide range of screws.

Discover it all on our online catalog.Every product is meticulously designed:

from head to tipDiscover our wide range of highly performing blockframe and drywall screws, all available in different sizes. Bugle head

Bugle headThis profile is designed to avoid the panel from breaking or sticking out.

Two-start thread

Two-start threadMultiple-start screws are designed to achieve large pitches without excessively lightening the core, which would compromise the mechanical strength of the screw itself.

Multi-fins

Multi-finsA finned screw is a standard element in mechanical engineering for manual adjustment functions. It is used as a fastening element in both internal and external parts.

Self-drilling tip

Self-drilling tipThe self-drilling tip is particularly used for fastening to malleable materials, such as drywall. It provides speed of fastening and greater grip even with shallower holes.

Guide to the fastener profilesThe transmission of force to the screw occurs through geometric coupling; therefore, each screw requires a counterpart suitable for its profile, in the form of a screwdriver, an hex key, or an insert. Here are the most common, from the classic profile to the most innovative ones.

TORXScrew with a head characterized by a six-pointed star-shaped recess: TX wafer head, TX hexagon washer head, TX truss head, TX cylinder head, TX flat head, TX truss washer head.POZIScrew with a crosshead featuring 4 integrated slots, similar to an asterisk: PZ flat – head, PZ pan head, PZ raised oval head, PZ and slotted combination truss head, PZ wafer head, PZ and slotted wafer head, PZ and slotted combination wafer head, PZ and slotted combination truss head.PHILLIPSScrew with an engraved crosshead, offering a good combination of stability and ease of use: PH bugle head, PH flat head, PH pan head, PH wafer head, PH truss washer head.HEXAGONHexagonal head screw with six sides forming between them an angle of 120°: Hexagonal head, hexagonal head with flange, hexagon flat washer head, hexagon socket truss head, hexagon socket cylinder head, hexagon countersunk socket flat head.SQUAREScrew with an engraved square drive, often used in industrial settings: square drive pan head, mushroom head square neck.SLOTScrew with an engraving in the form of a straight slot: slotted flat head, slotted raised oval head, slotted cheese head. Find the best deal for your businessExplore our online catalog, with 15 different families of screws, and discover a wide range of options to meet your specific fastening needs.NEW MILESTONES

Find the best deal for your businessExplore our online catalog, with 15 different families of screws, and discover a wide range of options to meet your specific fastening needs.NEW MILESTONES

OF EXCELLENCEQuality is the vector that makes our company stand out in a constantly evolving market. Our main mission is to achieve new levels of excellence in every reference sector, consistently expanding our range to meet the demands of an increasingly discerning professional clientele. When quality is involved there is no place for compromise, and the proof is in all of the products available in our catalog.FINISHES: PROTECTION AND CUSTOMIZATIONThe finishes of screws can vary significantly in terms of strength and aesthetic appearance, offering options to meet specific needs. Protective finishes are designed to shield screws from corrosion and wear ad tear, providing them with greater durability over time, making them ideal for applications in hostile environments or exposed to atmospheric agents. Aesthetic finishes are crafted to enhance the appearance of screws. They offer a more appealing smooth and shiny surface. They are often used in visible applications where appearance makes a difference. The selection of screw finishes is crucial to ensure they can reliably perform their function and seamlessly integrate into the overall project’s aesthetic appearance.

The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.THE QUALITY

The RoHS directive, staying for Restriction of Hazardous Substances, is a European law that limits the use of certain harmful substances in the manufacturing of commercial products. This regulation safeguards the quality of life and the environment by reducing the content of harmful substances such as lead, mercury, cadmium, and others. Compliance with the RoHS directive is synonymous with quality for marketing products in the European Union, thereby contributing to the promotion of the adoption of safer and more sustainable technologies.THE QUALITY

OF OUR SCREWSAmbrovit’s screw certifications are a fundamental to ensure the quality and safety of the products. Ambrovit is committed to meeting the highest production standards and providing screws that meet customer needs. These certifications testify to the company’s dedication to quality, safety, and compliance with regulations throughout the production process. Customers can therefore have confidence in using Ambrovit screws for their requirements, knowing that they meet rigorous standards and are suitable for a wide range of applications.Learn more about our products quality:AMBROVIT QUALITYLearn more about our products quality:AMBROVIT QUALITYWHERE EVERYTHING

IS CERTIFIEDDuring the years quality has become a pervasive value that involves every sector and department of the company, leading to the company obtaining ISO 9001 certification for the Quality Management System in 2011. Most products are equipped with varied certifications based on their type and intended use. Additional quality control tests are conducted internally on-site in collaboration with Uni Trento.

Ambrovit has achieved ISO 9001 certification, a recognition of quality and safety. To attain this certification, the company must demonstrate adherence to criteria such as advanced quality control, regulatory compliance, use of high-quality materials, product safety, and environmental commitment. Sustaining the certification demands a continuous dedication to improvement. This seal of approval serves as a robust indicator of reliability and quality, capable of bolstering customer confidence.

SCOPRI DI PIÙTÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures.

SCOPRI DI PIÙTÜV SÜD conducts periodic surveillance audits on all production processes, ensuring compliance with all requirements mandated by international regulations. Among these, the Euronorm 14592 is particularly relevant, and involves wood structures and connecting cylindrical elements. The standard outlines requirements and testing methods for materials, geometry, strength, rigidity, and durability of connecting cylindrical elements used in load-bearing wooden structures.

ISO 9001 certification serves as a seal of approval that highlights a manufacturing company’s consistent commitment to providing products of the highest quality, safety, and reliability. These products adhere to current regulations and are at the forefront of the industry. This recognition becomes a powerful marketing tool, assuring buyers that the products have undergone rigorous quality checks by an international organization.LEARN MOREETA (European Technical Assessment) certification is a European process of technical evaluation that assesses and approves the suitability of construction products in compliance with European regulations. This procedure is particularly relevant for the building and construction industry. The ETA certification process involves a comprehensive technical assessment by notified bodies, which examine products based on technical requirements and performance criteria.

SCOPRI DI PIÙETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

SCOPRI DI PIÙETA certification is voluntary and serves as a way to demonstrate product compliance with European technical specifications, especially when CE standard regulations are not directly applicable or complete.

Ambrovit proudly holds the ETA 16/0381 Certification for its entire range of carpentry screws, the ETA 18/1065 Option 1 Certification for anchoring screws in concrete, and the Post R Certificate of Conformity and Safety.

Once an ETA certification is obtained, products can be marketed in all European Union countries, facilitating their acceptance in the European market and transparently showcasing compliance with required technical standards. ETA certification is essential to ensure the quality and safety of construction products and to promote the free movement of goods within the EU.LEARN MORE